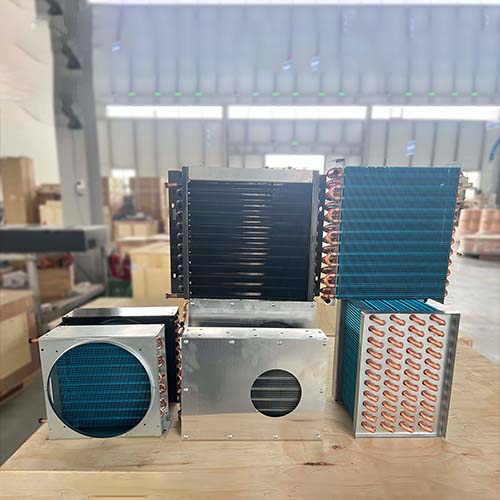

Co2 Condenser

CO2 Condenser is a key component in refrigeration systems, especially in systems that use carbon dioxide (CO2) as a refrigerant. Ⅰ. Definition and Function CO2 condenser is a heat exchanger u...CO2 Condenser is a key component in refrigeration systems, especially in systems that use carbon dioxide (CO2) as a refrigerant.

Ⅰ. Definition and Function

CO2 condenser is a heat exchanger used to cool and condense CO2 refrigerant from gas to liquid. In the refrigeration cycle, CO2 refrigerant absorbs heat and evaporates in the evaporator, then is compressed into a high-pressure and high-temperature gas by the compressor, and finally enters the condenser to release heat and condense into a liquid, completing a refrigeration cycle. Therefore, the main function of the CO2 condenser is to transfer the heat in the CO2 refrigerant to an external cooling medium (such as air or water), thereby achieving the condensation and recycling of the refrigerant.

Ⅱ. Structure and Features

1. Structure:

– CO2 condensers are usually made of steel pipes (or copper pipes) and are filled with CO2 refrigerant.

– The outer surface of the tube may be covered with fins or heat sinks to increase the heat exchange area and improve the heat exchange efficiency.

– The condenser is also equipped with inlet and outlet pipes for connecting the compressor and the evaporator.

2. Features:

– Efficient heat exchange: Since CO2 refrigerant has high thermal conductivity, CO2 condenser can achieve efficient heat exchange.

– Environmental protection: CO2, as a natural refrigerant, has the advantages of environmental protection, non-toxicity, non-flammability, etc., and is environmentally friendly.

– Wide applicability: CO2 condenser is suitable for various refrigeration systems, especially for occasions requiring efficient and environmentally friendly refrigeration.

III. Working principle

The working principle of CO2 condenser is based on the principle of heat exchange. When high-pressure and high-temperature CO2 refrigerant enters the condenser, it releases heat and gradually cools down by heat exchange with external cooling medium (such as air or water). With the release of heat and the decrease in temperature, CO2 refrigerant gradually condenses from gas to liquid. Finally, liquid CO2 refrigerant flows out of the condenser through the outlet pipe and enters the next refrigeration cycle stage.

IV. Application scenarios

CO2 condensers are widely used in various refrigeration systems, especially for occasions requiring efficient and environmentally friendly refrigeration. For example:

– Commercial refrigeration: such as supermarket refrigerated display cabinets, cold chain logistics vehicles, etc.

– Industrial refrigeration: such as the cooling process in the chemical and pharmaceutical industries.

– Household refrigeration: such as household refrigerators, air conditioners, etc. (Although the application of CO2 refrigerants in household refrigerators and air conditioners is relatively small at present, with the improvement of environmental awareness and the advancement of technology, its application prospects are broad).

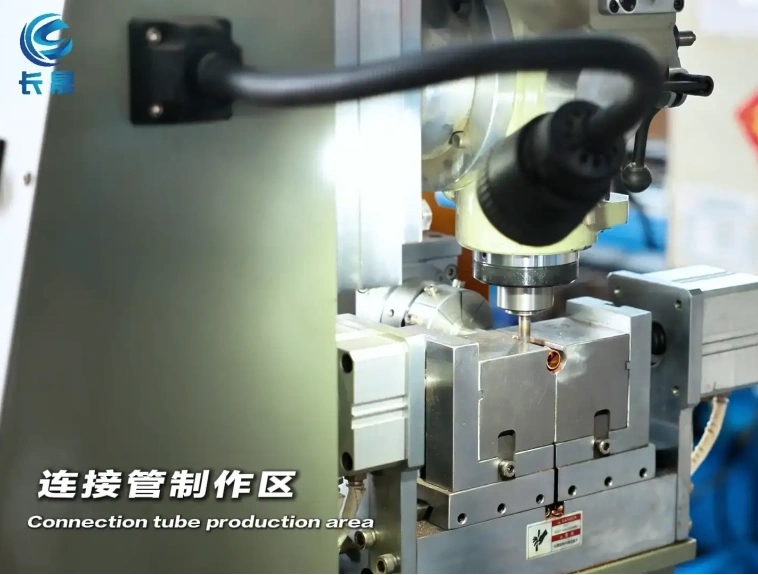

Factory Showcase

In summary, CO2 condensers are key components in refrigeration systems, with the characteristics of efficient heat exchange, environmental protection, and wide applicability. Regular maintenance and other measures can ensure the normal operation of CO2 condensers and extend their service life.

VIDEO INTRODUCTION

You Might Also Like

Send Inquiry