Cooling system

The cooling system is a crucial process step in sandwich panel production, particularly in continuous PU/PIR production lines. Its core function is to forcibly and uniformly cool the sandwich panel to near room temperature after foaming and high-temperature curing. This ensures the panel's dimensional stability and mechanical properties meet standards, allowing it to meet the requirements of subsequent stacking and packaging processes.Simply put, it serves as a "forced cooling" process for hot panels fresh from the oven.Cooling System Composition and Operation

The cooling system is typically located after the double-belt laminator and before the cutting saw. Its main components and operating principles are as follows:

1. System Configuration

Cooling Section: An independent frame structure ranging from several to over ten meters in length.

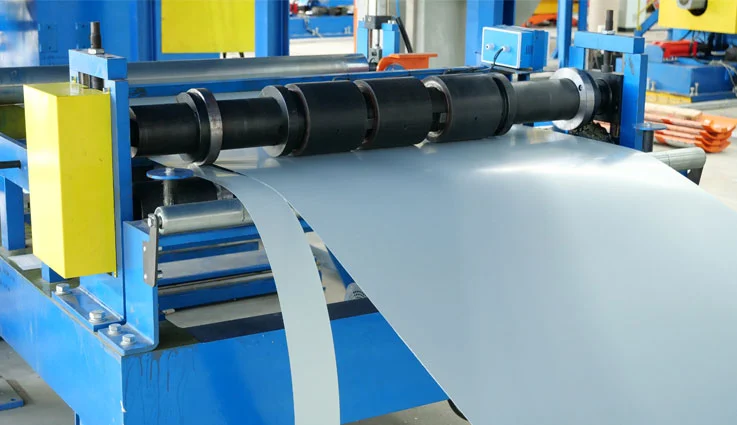

Cooling Conveyor: Typically employing rollers or belts synchronized with the main production line, this ensures smooth passage of the sheets through the cooling zone without surface scratches.

Forced Cooling: This is the core of the system and comes in two main forms:

Air Cooling: The most common method. It consists of a high-power fan, ducts, and nozzles. Cool air is drawn in from the workshop or outside by the fan and blown evenly across the upper and lower surfaces of the sheets through a carefully designed array of nozzles, removing heat through convection.

Water Cooling (Less common, used for specific needs): This system utilizes cooling water circulation, which is conducted through cooling plates or specialized jackets that contact the back of the sheets. This system is more efficient but also complex.

2. Workflow: The hot sheets exit the laminator and enter the cooling section.

The conveyor transports the sheets at a speed synchronized with the production line. The fan activates, blowing a large amount of room-temperature air evenly and vertically onto the upper and lower surfaces of the board.

As the board moves at a constant speed, heat is removed by the continuously flowing air, causing its temperature to gradually and evenly drop from the inside out.

After a sufficient cooling distance and time, the board’s overall temperature has dropped to the ideal range of ±5°C above room temperature (typically below 40°C) by the time it reaches the saw.

The cooled boards are then precisely cut and stacked.

Gallery of Polyurethane Continuous Sandwich Panel Production Line

Previous

Cutting systemNext

Stacking systemYou Might Also Like

Send Inquiry