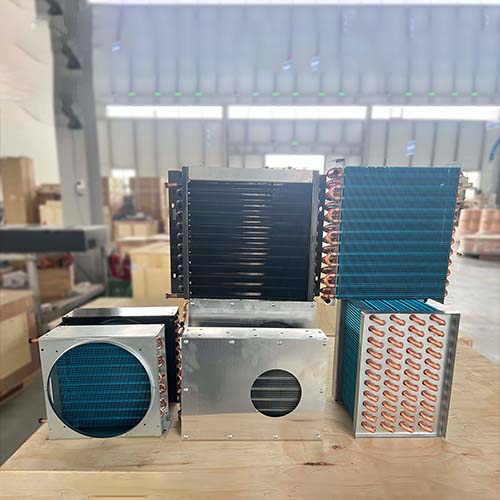

Copper Tube Aluminum Fin Evaporator Heat Exchanger

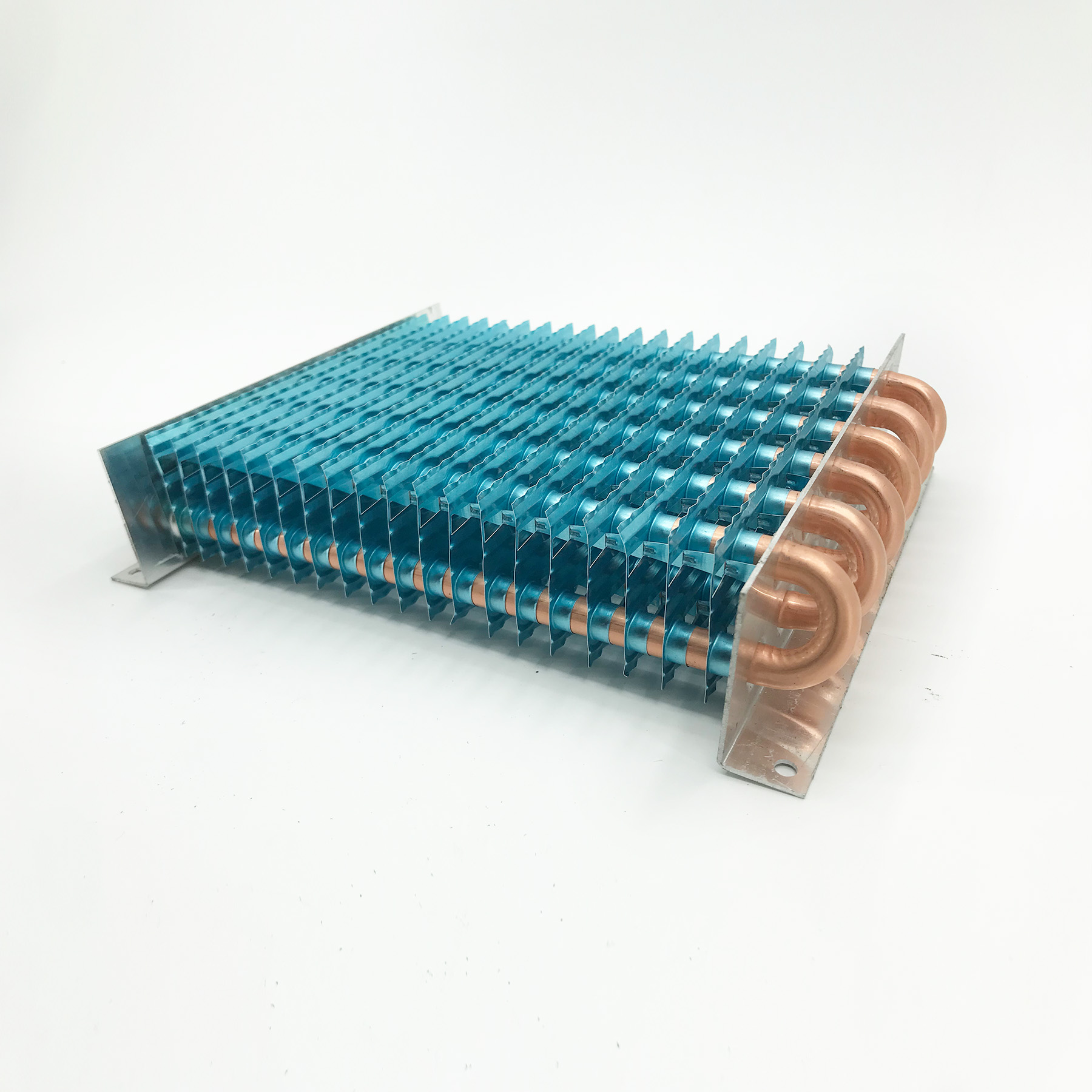

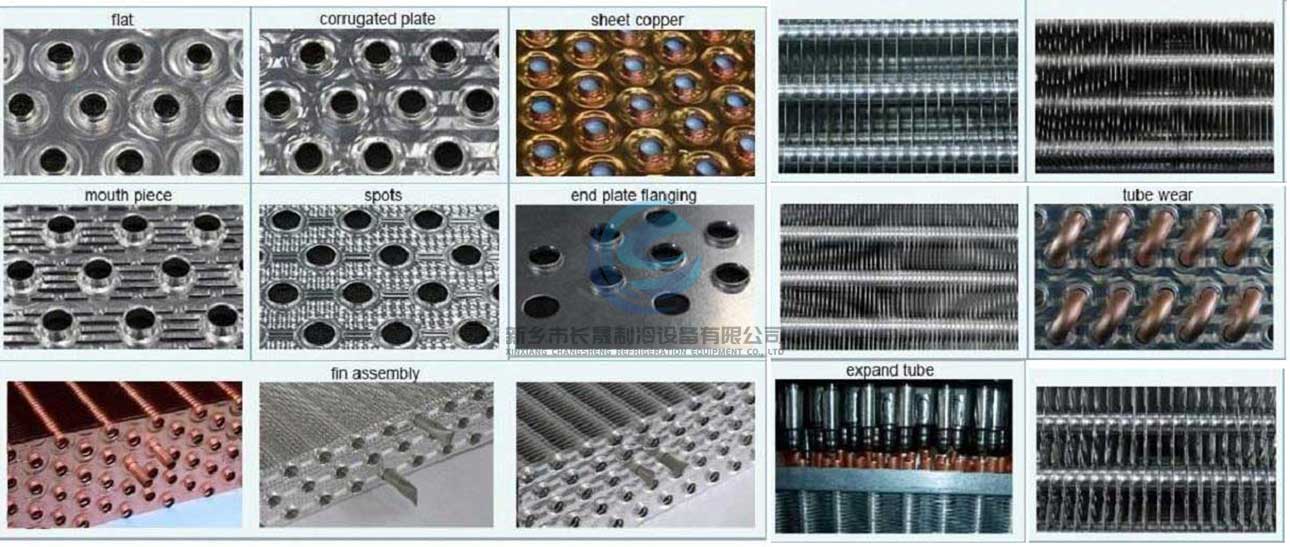

- 1.Tubes and Fins: Copper, cupro-nickel, aluminum, titanium and stainless steel

- 2. Tube Diameters: According to our fin mold, most common is 9.52mm, 12.75mm and 15.88mm

- 3. Casings: standard is galvanized steel, Aluminum and stainless steel for option

Copper Tube Aluminum Fin Evaporator Heat Exchanger is a highly efficient heat exchange equipment widely used in refrigeration, air conditioning and freezing.

1. Copper tube: As the main flow channel of refrigerant, copper tube has good thermal conductivity and corrosion resistance, and can effectively transfer heat.

2. Aluminum fin: Aluminum fins are tightly attached to copper tubes, which greatly increases the heat exchange area and improves the heat transfer efficiency. The fins can be flat or corrugated, hydrophilic or bare to meet different application requirements.

3. Other components: In addition to copper tubes and aluminum fins, evaporator heat exchangers also include inlet and outlet pipes, brackets, seals and other components to ensure the normal operation and stability of the equipment.

Features and advantages

2. Strong corrosion resistance: Both copper tubes and aluminum fins have good corrosion resistance and can adapt to various harsh working environments.

3. Compact structure: The evaporator has a compact structure, small footprint, and is easy to install and maintain.

4. Strong adaptability: It can be customized according to different application requirements, such as different refrigerants, different fin types, different tube diameters, etc.

Workshop

Working principle

2. Heat exchange process: The refrigerant on the aluminum fin exchanges heat with the surrounding air, absorbing heat from the air and transferring it to the refrigerant. At the same time, the refrigerant in the copper tube is also constantly evaporating and flowing, taking away the heat and transferring it to the condenser.

3. Air cooling: The air passing through the evaporator is cooled and the temperature is reduced, thereby achieving the purpose of refrigeration or air conditioning.

Application fields

2. Air conditioning industry: used for refrigeration and heating of air conditioning systems such as central air conditioning and household air conditioning.

3. Other fields: can also be used for refrigeration and temperature control in food preservation, pharmaceutical refrigeration, chemical production and other fields.

Q1: How can I make an order? A1: Inquiry → Quotation → Order → Payment → Delivery → Deal → Feedback Q2: What is your terms of payment? A2: T/T 30% as deposit, and 70% before delivery. We ll show you the photos of the products and packages before you pay the balance. Q3: What is your terms of delivery? A3:Convenience by Western Union/Money Gram/Trade Assurance/Paypal/T/T etc. Q4: How about your delivery time? A4: Generally, it will take 15 to 40 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order. Q5: Can you produce according to the samples? A5: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures. Q6: What is your sample policy? A6: We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and the courier cost. Q7: Do you test all your goods before delivery? A7: Yes, we have 100% test before delivery Q8: How do you make our business long-term and good relationship? A8: 1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them,

no matter where they come from. Q9: What is your Minimum Order Quality? A9: Different products have different MOQ,but we can sell you even one piece if we have stock the model of you need.FAQ

VIDEO INTRODUCTION

You Might Also Like

Send Inquiry