Cutting system

The cutting system is an essential component of a continuous sandwich panel production line. Its core function is to precisely and efficiently cut panels to length while the line continues to operate and advance at a constant speed. It also transmits the cutting signal to the downstream stacking system, transforming the endlessly long continuous panels into finished products of specific lengths that meet customer orders. Simply put, it's an automated unit that performs "precision surgery at high speed." The cutting system is typically located at the end of the production line, after the cooling system and before the stacking system.

The cutting system is typically located at the end of the production line, after the cooling system and before the stacking system.

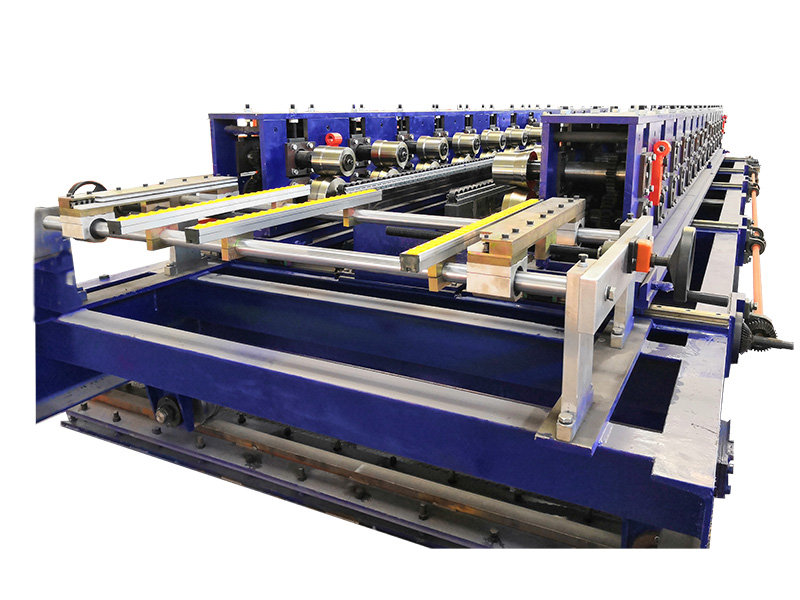

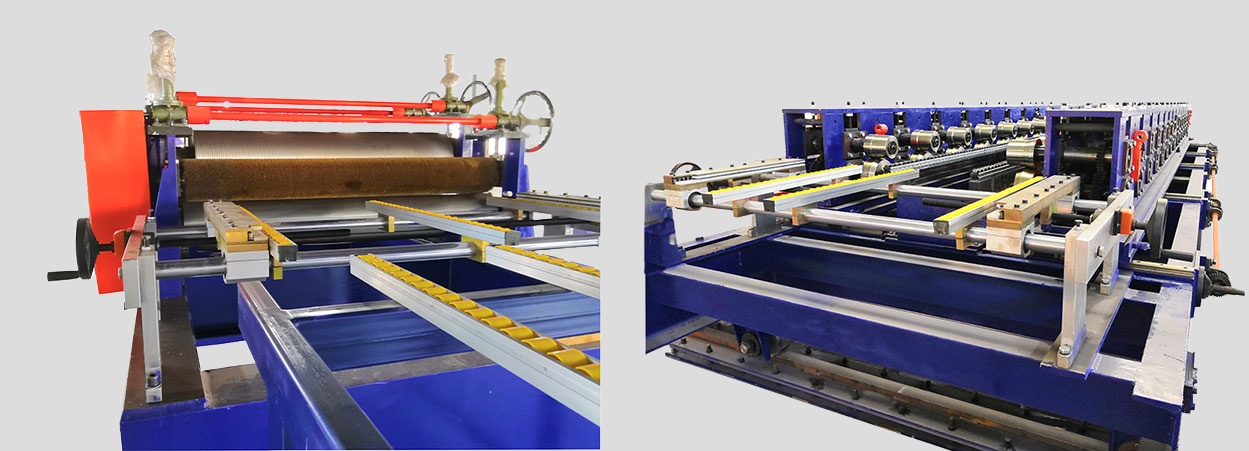

1. System Configuration

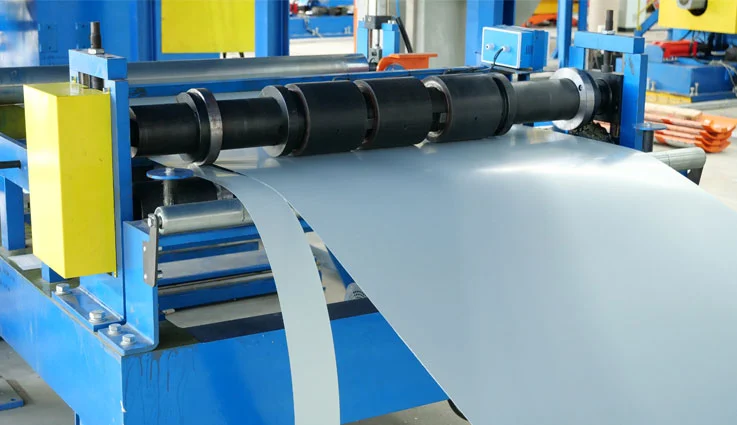

Cutting Machine: Typically, it consists of a motor assembly equipped with a high-speed cutting saw blade (alloy or diamond).

Moving Carriage (Flying Carriage): Carries the cutting machine and is mounted on a precision guide rail parallel to the production line.

Servo Drive System: Provides power to the moving carriage, precisely controlling its acceleration, constant speed, deceleration, and return.

Clamping Device: Securely secures the sheet metal from above, below, or laterally at the moment of cutting to prevent vibration and movement, ensuring a smooth cut.

Dust Removal System: A dust hood and external dust collector connected to the cutting head collect metal and foam debris generated during cutting, protecting the equipment and the working environment.

Control System: Receives speed signals and set length commands from the production line, accurately calculates and directs the servo system to synchronize cutting.

2. Workflow (“Synchronized Cutting” Principle)

This is the technical essence of the cutting system, a process comparable to the docking of a “flying formation”:

Synchronized Acceleration: When the control system calculates the required cut based on the preset length, the mobile carriage begins to move and rapidly accelerates to a speed completely synchronized with the production line. At this point, the saw blade is moving relative to the ground but stationary relative to the steadily advancing sheet material.

Cutting Operation: At the moment of speed synchronization, the clamping device activates to secure the sheet material, and the high-speed saw blade then advances to complete the cut. Because the two speeds are synchronized, the cutting process is smooth, resulting in a vertical, burr-free cut.

Deceleration and Return: After the cut is completed, the clamping device releases, the carriage automatically decelerates and stops, then returns to its starting position at high speed.

Wait for Next Cycle: After the carriage returns to its starting point, it awaits the next cut command and the above process repeats.

Gallery of Polyurethane Continuous Sandwich Panel Production Line

Next

Cooling systemYou Might Also Like

Send Inquiry