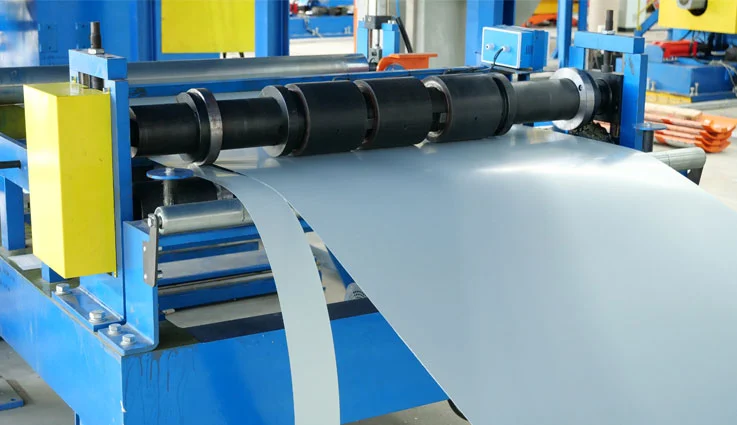

Decoiling system

A roll-forming system, also known as a cold-roll forming system or flow-forming system, is a key front-end process in a continuous sandwich panel production line. Its core function is to continuously plastically deform flat metal sheets (such as color-coated steel and galvanized steel) supplied in coil form at room temperature using multiple pairs of precisely contoured rollers arranged in a specific sequence, gradually rolling them into the specific cross-sectional shape required by the design, thus providing qualified panels for subsequent foaming and lamination. Simply put, it's a "metal sculptor," "sculpting" the ordinary metal coil into the final sandwich panel shape.1. System Configuration

Uncoiler (coil support): Core equipment used to support and rotate coils. Mainly categorized as:

Cantilever uncoiler: Most commonly used in sandwich panel production lines. One end of the coil is fixed, while the other is suspended, facilitating rapid loading and unloading using a crane or loading trolley.

Double-head uncoiler: Supported at both ends, suitable for extremely heavy and large coils.

Loading trolley (optional but commonly used): Auxiliary equipment used to transport heavy coils from the storage area to the uncoiler and assist in accurately inserting them onto the uncoiler drum.

Drum: Inserted into the center hole of the coil, it locks the coil’s inner diameter using an expansion mechanism (such as a fan plate) and transmits torque.

Drive and Braking System: A motor drives the drum to rotate and unwind, and is equipped with a precision brake to provide controlled back tension.

Straightener (primary straightening): Typically composed of 5-9 staggered straightening rollers, this system repeatedly bends the strip to eliminate longitudinal curl stress and flatten it.

Center Position Control (CPC): Consists of a photoelectric sensor, controller, and hydraulic/electric actuator. The sensor monitors the strip edge position in real time. If any deviation from the centerline is detected, the controller immediately instructs the actuator to fine-tune the entire uncoiler base or guide rollers to maintain centering.

Guide: A series of fixed or adjustable vertical rollers that guide the strip into subsequent equipment and prevent it from swinging.

2. Workflow

Loading: The coil is hoisted onto the uncoiler’s drum using a crane or dedicated loading vehicle. The drum’s expansion mechanism is activated to lock the coil’s inner bore.

Feeding: The coil’s head is manually pulled through the straightener and guide device, and then fed into the subsequent roll-forming machine’s entry pinch rollers.

Starting Production: The production line starts, and the subsequent forming machine acts as the main drive to pull the strip.

Synchronization and Control: The uncoiler’s drive/brake system automatically adjusts the unwinding speed based on line speed and tension feedback, providing stable back-tension. Simultaneously, the CPC system continuously operates to ensure strip centering.

Roll Changing and Splicing (High-End Production Lines): When a roll of material is exhausted, some fully automated production lines are equipped with a dual-station uncoiler and stitching machine. While one station is producing, the other station prepares a new roll and welds or rivets the ends of the new and old strip together, enabling automatic roll changes without stopping the line and ensuring absolute production continuity.

Gallery of Polyurethane Continuous Sandwich Panel Production Line

Previous

PU sandwich panel lineNext

Roll Forming SystemYou Might Also Like

Send Inquiry