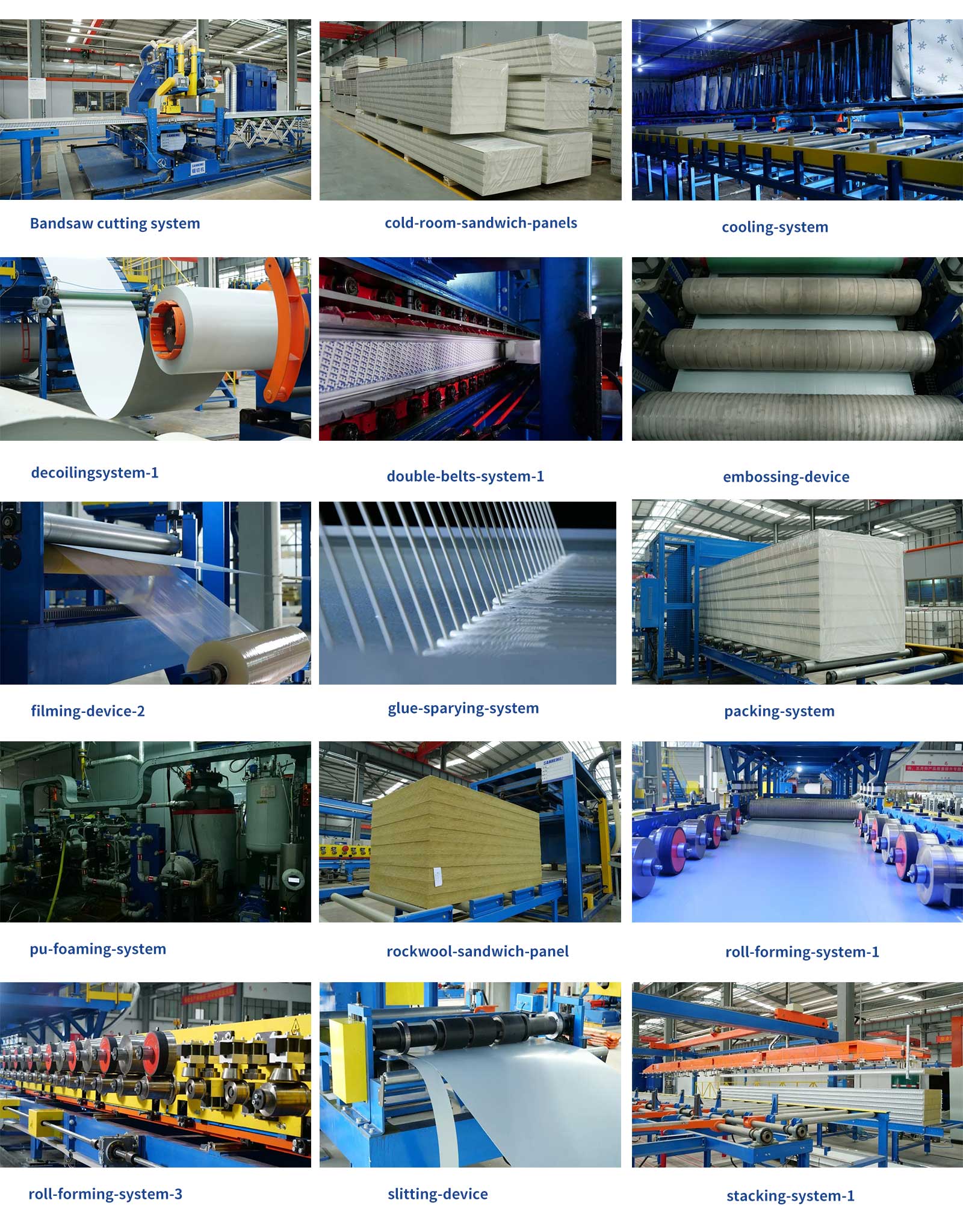

Double belt slat conveyor(caterpillar) system

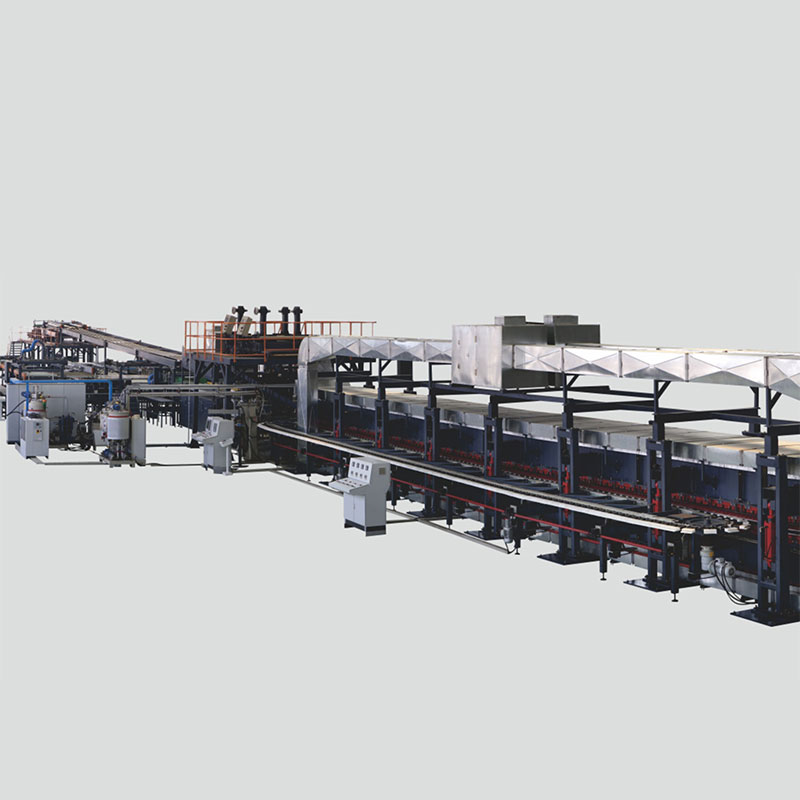

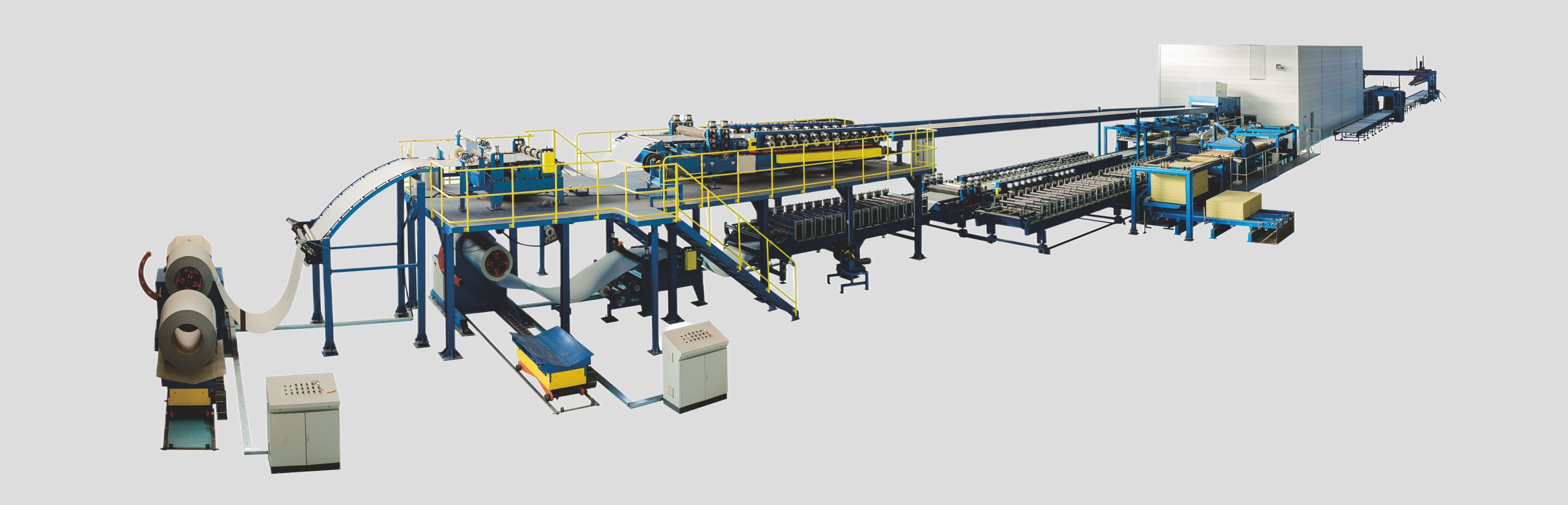

The double-belt plate conveyor system, commonly known as a laminator or crawler conveyor, is the heart and core molding device of a polyurethane (PU/PIR) continuous sandwich panel production line. It is a large, continuously operating precision pressure vessel and heating furnace combination.1. System Configuration

A complete dual-belt system typically consists of the following components:

Frame: A massive, sturdy steel frame serves as the foundation of the entire equipment.

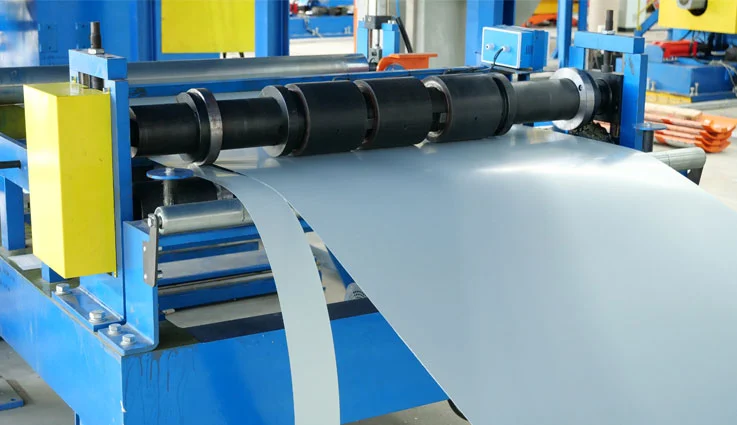

Upper and lower steel tracks: These are the system’s core operating components. Each track is composed of hundreds of precision-machined heating plates connected by articulated shafts, forming a massive, revolving “plate chain.”

Heating System: Pipes are typically embedded within the heating plates, feeding thermal oil or steam to provide a uniform and stable heat source throughout the track. Advanced systems utilize zoned temperature control to precisely adjust the temperature in different areas.

Pressure Control System: This system comprises a complex hydraulic or pneumatic system that precisely controls the forming pressure by adjusting the gap between the upper and lower tracks and the pressure applied to the tracks.

Drive System: A high-power motor drives a sprocket, driving the massive tracks to run smoothly at a speed synchronized with the production line.

Gap Adjustment Device: This device precisely adjusts the gap between the upper and lower tracks, effectively setting the final plate thickness. Modern equipment utilizes CNC electric thickness adjustment for exceptional precision.

2. Workflow (“Moving Mold”)

Preparation: The lower metal panel is formed, and the liquid mixed chemical raw material is evenly poured onto it by a high-pressure foaming machine.

Entry: The lower panel, containing the raw materials, is fed from the laminator’s infeed into the mold cavity between the upper and lower tracks along with the upper panel.

Reaction and Forming:

Pressure: The hydraulic system pushes the upper track downward, applying a set pressure to the “sandwich” structure.

Heating: The high-temperature tracks continuously heat the upper and lower surfaces of the panel, triggering and accelerating the chemical reaction (foaming and curing) of the core material.

Confinement: Under the combined effects of pressure and heat, the raw materials foam, fill, and cure within the confined space, firmly bonding to the metal panel.

Discharge: The fully reacted and cured sandwich panel is continuously discharged from the laminator’s discharge end and enters the cooling section.

The entire process is like a “precision mold of infinite length and constant speed.”

Gallery of Polyurethane Continuous Sandwich Panel Production Line

Previous

Roll Forming SystemNext

Cutting systemYou Might Also Like

Send Inquiry