EPS Sandwich Panel Production Line

The EPS sandwich panel production line is a specialized system for the continuous, automated production of composite sandwich panels with expanded polystyrene (EPS) as the core material and metal sheets (such as color-coated steel sheets) or non-metallic panels as the surface layers.14 Its core value lies in the simultaneous molding of insulation materials and high-strength panels on the production line, producing insulating panels widely used in the construction industry.

Main structure features of EPs Sandwich Panel Machine

1) This EPS sandwich panel making machine has the specification: nice appearance, low noise and high efficiency.2) The EPs sandwich panel production ine is welded by H-beam with shot blasting treatment on the surface, so the whole structure is simple and stable.3)Consecutive laminating body transmissionof the EPS sandwich panel making machine adopts worm and worm gear in order to control the producing speed steadily. Theconsecutive laminating body can cut to length with the advanced frequency control.4) The EPs sandwich panel machine is equipped with three groups heating system to adapt the environmental temperature in diferent places.5) Glue Providing system of our EPs panel machine is driven individually. The horizontal compound, glue evenly, without any pollution.6) Consecutive laminating body is long to quarantee the flatness of the sandwich panel7) The moving stroke of the cutting system is long to extend the life of the cutting tool

Contact us for EPS sandwich panel machine price! 0r contact us for more information about other sandwich panel production machinery/line。

Main Structure Components Of EPS Sandwich Panel Production Line

This EPs sandwich paneline consists of one rolforming machine and one laminating machine.t adopts interationalrolfoming technology, laminating transmision technologyair-actuated and electric & hydraulic control technology. The whole EPs panel production line only needs 6 or 7 workers.

The whole sandwich panel machine line consists of two parts: roll forming part and laminator part

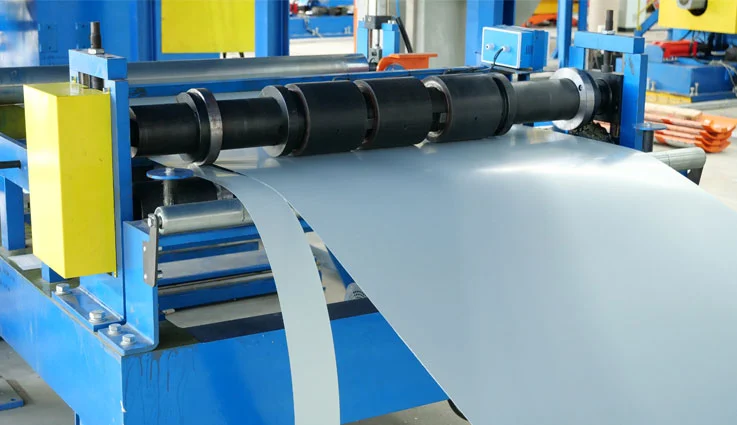

1) Roll forming part

The rol forming machine consists of a hydraulic uncoiler, quiding system, flming system,fat sheet siting system, rollforming system, panel suport frame, assistant forming

machine and so on.

2) Laminating body

This part consists of a quiding device,laminating body, cuting system, glue feeding system, support device and electric control system, etc.

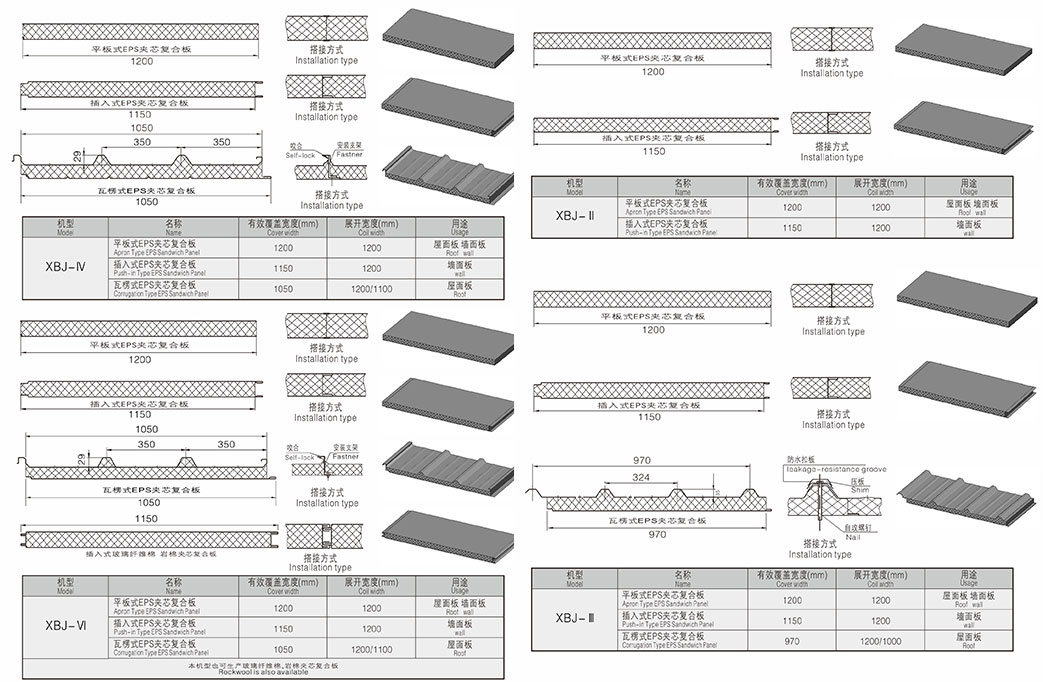

Panel Drawings Of EPS Sandwich Panel Production Line

Previous

Wrapping systemYou Might Also Like

Send Inquiry