1. Notes on no-load debugging

Observation of the operation of the motor and transmission components: After turning on the power and starting the motor, pay close attention to the direction of rotation of the reel. If the direction is wrong, stop the machine immediately and check the motor wiring to avoid damaging the equipment components due to reverse rotation. At the same time, listen carefully to the sound of the transmission components in operation, such as gears, chains, belts, etc. Normal operation should be smooth and without sharp friction or impact sounds. Once abnormal noise occurs, it may mean that the components are improperly installed, insufficient lubrication or worn, and need to be checked and repaired in time.

Lubrication system inspection: When running without load, check the oil flow of each lubrication point. The lubricating oil should be able to smoothly reach all parts that need lubrication, such as bearings, guide rails, etc. You can judge whether the lubrication system is working properly by observing whether there are oil marks near the lubrication points and using professional tools to detect whether the lubricating oil pressure is within the normal range. If the lubrication is poor, it will aggravate the wear of components and reduce the service life of the equipment. Problems in the lubrication system must be solved in time, such as unblocking the oil circuit and replenishing the lubricating oil.

2. Notes on load debugging

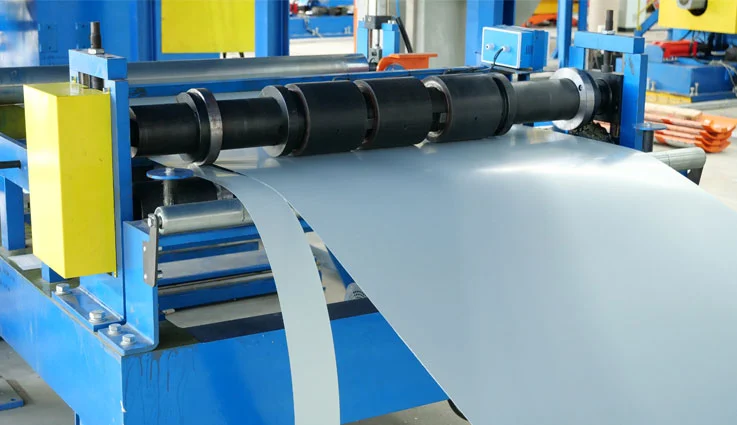

Coil unwinding status monitoring: When installing the coil on the unwinder for load debugging, focus on observing whether the coil unwinding process is smooth. The coil should not be wrinkled, deviated, or torn. If the coil is found to be unsteady, it may be due to improper tension control, non-parallel axis of the roll, or mechanical failure of the equipment. It is necessary to adjust the tension system in time, check the installation accuracy of the roll, and troubleshoot the mechanical parts of the equipment.

Check the load condition of equipment components: gradually increase the unwinding speed and tension, and pay close attention to whether each component has signs of overload during this process. Observe whether the motor current is within the rated range. If the current is too large, it means that the motor load is too heavy, which may be due to excessive equipment resistance or unreasonable parameter settings. At the same time, check whether the transmission components are overheated. You can measure the temperature by touching (be careful to prevent burns) or using a thermometer. If the temperature is too high, it may be due to excessive friction of the components. Check the installation and lubrication of the components.

3. Precision detection precautions

Selection of measuring tools and methods: It is crucial to use professional measuring tools for accuracy testing. For example, to measure the radial runout and axial runout of the roll, a high-precision dial indicator should be selected and correctly installed in the measuring position. When measuring the unwinding accuracy, advanced equipment such as laser measuring instruments can be used to ensure that the measurement data is accurate and reliable. During the measurement process, strictly follow the operating instructions of the measuring tool to ensure the correct measurement method and avoid measurement errors caused by improper operation. Comparison and adjustment of accuracy standards: Compare the measured accuracy indicators with the design standards or production requirements of the equipment.

Powerful Solutions

If the accuracy deviation is within the allowable range, the data can be recorded as a basic reference for equipment operation; if the deviation exceeds the allowable range, it must be adjusted in time. When adjusting, it is necessary to analyze the possible causes according to the specific deviation, such as loose mechanical parts, offset installation position, etc., and then perform targeted tightening, calibration and other operations until the equipment accuracy meets the requirements.

If you want to know more about Decoiler Slitter Coiler Line, Welcome to contact Jinye at any time!