Abstract: This paper introduces the common anti-corrosion methods for air-cooled condensers, compares the differences in the common anti-corrosion methods for condensers, and uses the concept of average heat transfer coefficient to illustrate that it is necessary and important to use anti-corrosion technology for condensers. In addition, the performance and characteristics of Blygold anti-corrosion coating are introduced.

Keywords: condenser, anti-corrosion, Blygold, gold foil, average heat transfer coefficient, computer room air conditioning

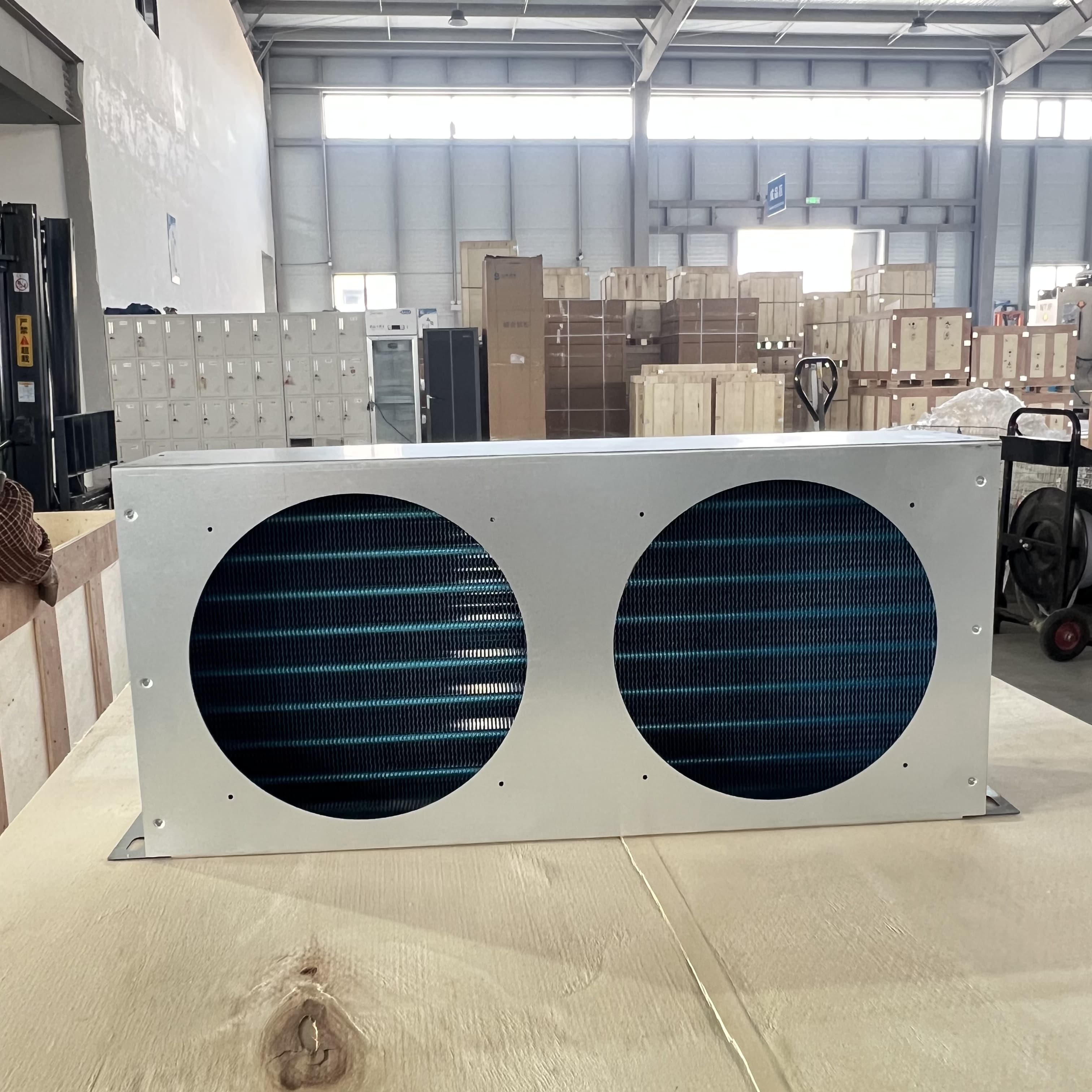

The air-cooled condenser of the split air-conditioning unit is installed in an outdoor environment. Compared with the indoor installation environment, its working conditions are much worse. Therefore, it is easy to have corrosion, dust accumulation and other phenomena, which will reduce the performance and life of the air-cooled condenser. Therefore, it is very important to provide special protection for the air-cooled condenser.

The air-cooled condensers used in air-conditioning equipment all use copper tube aluminum fin heat exchangers. Generally speaking, this type of heat exchanger itself has good corrosion resistance, so people don’t pay much attention to its corrosion protection. However, this concept needs to be changed.

From the perspectives of energy efficiency, equipment life and maintenance cost, it is very necessary to prevent corrosion of air-cooled condensers.

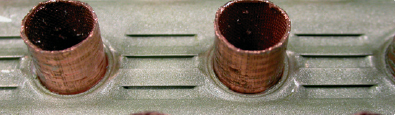

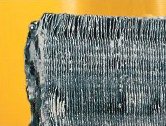

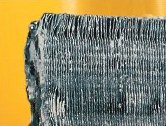

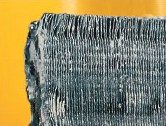

Below is a picture of a corroded condenser:

Obviously, when the condenser is corroded, the following problems will occur:

- The surface fouling factor increases significantly (heat transfer performance decreases)

- Heat transfer material decay

- Dust accumulates easily (reduced heat transfer performance, reduced air flow capacity)

The end result is: the condenser fails and cannot be used.

The corrosion rate of the condenser is related to the corrosive components in the air of the installation environment, the amount of dust and the content of corrosive impurities therein, and the air humidity. The relationship between these influencing factors and the corrosion rate is as follows:

- The higher the dust content in the air, the faster the condenser corrodes

- The more corrosive gases there are in the air and the higher their content, the faster the corrosion rate.

- The higher the air humidity, the faster the corrosion rate

Although the corrosion rate of condensers varies in different working environments, it is still an important issue that users should pay full attention to during product installation and use. However, if this issue is taken seriously during product procurement, the problem can be solved fundamentally. That is to say, when purchasing condensers, suppliers should be required to carry out anti-corrosion treatment on the condensers and anti-corrosion should be regarded as a basic technical requirement for condensers.

Anti-corrosion treatment of the condenser can provide the following benefits:

- Extend the life of the condenser

- Improve average heat transfer efficiency, thereby reducing operating energy consumption

- Reduce condenser maintenance workload or maintenance costs

It should be noted that the concept of average heat transfer efficiency mentioned here refers to the average value of the heat transfer coefficient at different time points during the entire working process of the condenser. We know that after adding a protective layer to the heat transfer surface of the condenser, generally speaking, its heat transfer coefficient is reduced because the thermal resistance increases. However, we need to take into account that after the heat transfer material of the condenser is corroded, the thermal resistance will rise rapidly, so the heat transfer coefficient will drop rapidly. If the anti-corrosion measures are good, although the initial heat transfer coefficient is reduced, the average heat transfer coefficient is high throughout the life cycle, so adding an anti-corrosion coating to the condenser is conducive to energy-saving operation. In addition, the anti-corrosion coating prolongs the service life and reduces maintenance costs, so we recommend that users should give priority to products with anti-corrosion coatings when purchasing such air-conditioning equipment.

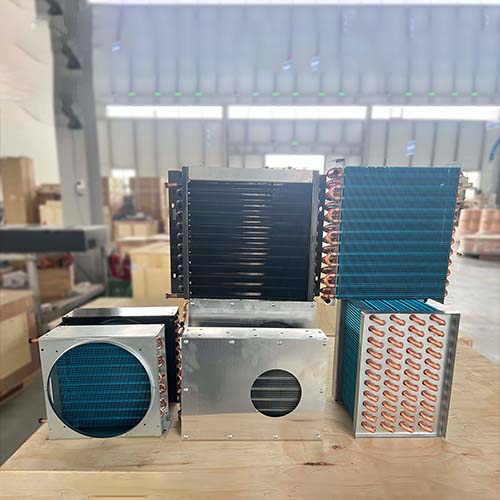

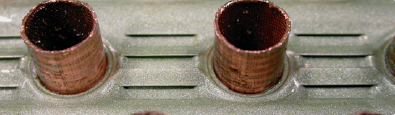

By comparing the two sets of pictures below, we can easily understand the meaning of the above content.

In the above picture, the left picture shows the state of the condenser that has not been treated with anti-corrosion after being used in a corrosive environment for a period of time, and the right picture shows the state of the condenser that has been treated with anti-corrosion after being used in the same environment for several years.

There are two basic ways to treat the surface of the condenser for corrosion protection:

1: Anti-corrosion coating: The surface of the heat exchanger aluminum foil is pretreated with anti-corrosion coating, generally using an epoxy resin coating, which is directly applied to the surface when the aluminum foil is formed.

2: Post-anti-corrosion coating: After the entire heat exchanger is processed and formed (after the copper tube and aluminum foil are combined), a protective layer is sprayed on the surface of the aluminum foil.

The first method has high processing efficiency and low cost, but the overall heat transfer performance of the heat exchanger is poor, while the latter is the opposite. The main difference is shown in the figure below:

Condenser aluminum tube aluminum fin anti-corrosion coating structure comparison chart

In the above figure, the left figure shows the structure of the copper tube aluminum fin condenser with anti-corrosion coating, and the right figure shows the condenser structure with post-anti-corrosion coating. Among them, the anti-corrosion coating structure has an additional layer of anti-corrosion coating between the fins and the copper tubes compared to the post-anti-corrosion coating structure. According to the principle of heat transfer, this coating has a greater impact on the heat transfer performance of the heat exchanger. In order to achieve better protection performance and ensure heat transfer efficiency, the post-protection coating process should be used first.

There are two process methods for implementing post-protective coating:

- On-site spraying

- Factory-specific equipment spraying

Obviously, the quality of spraying by factory-specific equipment is better, with the characteristics of thinner coating (lower thermal resistance) and more uniform (lower average thermal resistance).

As a typical representative of condenser protective coatings, Blygold gold foil anti-corrosion coating is the best product on the market. This anti-corrosion coating is a polyurethane aluminum compound with excellent weather resistance and good thermal conductivity. It only needs to be sprayed with a very thin layer on the surface of the heat exchanger to provide good and lasting protection for the condenser without reducing the heat transfer capacity of the condenser.

The main characteristics of Blygold coatings for condenser protection are as follows:

| name: | Blygold PoluAl XT |

| Paint Type: | Colored polyurethane aluminum |

| color: | champagne |

| Preprocessing | Removing oil stains |

| Temperature range (dryness): | -20°C to 150°C (-4°F to 302°F) |

| Applications: | Aluminum and copper |

| ASTM B117: | 4000+ hours (moderate salt spray test) |

| ASTM B-287: | 4000+ hours (acid salt spray test) |

| Sulfur resistance test: | 80 cycles |

| Coating thickness: | 25-30 μm (1 mil) |

| Impact test: | 0-5% (related to the geometric characteristics of aluminum foil) |

| Thermal resistance: | 0-3% (related to the geometric characteristics of aluminum foil) |

| operate: | Professional operators |

| UV resistance: | Excellent |

| Adhesion (planning method): | 0 (Europe) 5b (America) |

| application: | Corroded heat exchanger surfaces |

| Chemical resistance: | Excellent |

Finally, it should be noted that although the use of anti-corrosion coating on the condenser increases the cost to a certain extent, the proportion of this cost is not large compared to the whole air conditioner. What is important is that the energy cost saved in the entire life cycle of the air conditioner is considerable, and the maintenance cost is also reduced. It is recommended that users, especially users of computer room air conditioner products, pay full attention to the application of this technology, because computer room air conditioner products work 8760 hours a year, and its advantages and cumulative benefits are very obvious.

Importance and anti-corrosion methods of air-cooled copper tube finned condensers

Abstract: This paper introduces the common anti-corrosion methods for air-cooled condensers, compares the differences in the common anti-corrosion methods for condensers, and uses the concept of average heat transfer coefficient to illustrate that it is necessary and important to use anti-corrosion technology for condensers. In addition, the performance and characteristics of Blygold anti-corrosion coating are introduced.

Keywords: condenser, anti-corrosion, Blygold, gold foil, average heat transfer coefficient, computer room air conditioning

The air-cooled condenser of the split air-conditioning unit is installed in an outdoor environment. Compared with the indoor installation environment, its working conditions are much worse. Therefore, it is easy to have corrosion, dust accumulation and other phenomena, which will reduce the performance and life of the air-cooled condenser. Therefore, it is very important to provide special protection for the air-cooled condenser.

The air-cooled condensers used in air-conditioning equipment all use copper tube aluminum fin heat exchangers. Generally speaking, this type of heat exchanger itself has good corrosion resistance, so people don’t pay much attention to its corrosion protection. However, this concept needs to be changed.

From the perspectives of energy efficiency, equipment life and maintenance cost, it is very necessary to prevent corrosion of air-cooled condensers.

Below is a picture of a corroded condenser:

Obviously, when the condenser is corroded, the following problems will occur:

- The surface fouling factor increases significantly (heat transfer performance decreases)

- Heat transfer material decay

- Dust accumulates easily (reduced heat transfer performance, reduced air flow capacity)

The end result is: the condenser fails and cannot be used.

The corrosion rate of the condenser is related to the corrosive components in the air of the installation environment, the amount of dust and the content of corrosive impurities therein, and the air humidity. The relationship between these influencing factors and the corrosion rate is as follows:

- The higher the dust content in the air, the faster the condenser corrodes

- The more corrosive gases there are in the air and the higher their content, the faster the corrosion rate.

- The higher the air humidity, the faster the corrosion rate

Although the corrosion rate of condensers varies in different working environments, it is still an important issue that users should pay full attention to during product installation and use. However, if this issue is taken seriously during product procurement, the problem can be solved fundamentally. That is to say, when purchasing condensers, suppliers should be required to carry out anti-corrosion treatment on the condensers and anti-corrosion should be regarded as a basic technical requirement for condensers.

Anti-corrosion treatment of the condenser can provide the following benefits:

- Extend the life of the condenser

- Improve average heat transfer efficiency, thereby reducing operating energy consumption

- Reduce condenser maintenance workload or maintenance costs

It should be noted that the concept of average heat transfer efficiency mentioned here refers to the average value of the heat transfer coefficient at different time points during the entire working process of the condenser. We know that after adding a protective layer to the heat transfer surface of the condenser, generally speaking, its heat transfer coefficient is reduced because the thermal resistance increases. However, we need to take into account that after the heat transfer material of the condenser is corroded, the thermal resistance will rise rapidly, so the heat transfer coefficient will drop rapidly. If the anti-corrosion measures are good, although the initial heat transfer coefficient is reduced, the average heat transfer coefficient is high throughout the life cycle, so adding an anti-corrosion coating to the condenser is conducive to energy-saving operation. In addition, the anti-corrosion coating prolongs the service life and reduces maintenance costs, so we recommend that users should give priority to products with anti-corrosion coatings when purchasing such air-conditioning equipment.

By comparing the two sets of pictures below, we can easily understand the meaning of the above content.

In the above picture, the left picture shows the state of the condenser that has not been treated with anti-corrosion after being used in a corrosive environment for a period of time, and the right picture shows the state of the condenser that has been treated with anti-corrosion after being used in the same environment for several years.

There are two basic ways to treat the surface of the condenser for corrosion protection:

1: Anti-corrosion coating: The surface of the heat exchanger aluminum foil is pretreated with anti-corrosion coating, generally using an epoxy resin coating, which is directly applied to the surface when the aluminum foil is formed.

2: Post-anti-corrosion coating: After the entire heat exchanger is processed and formed (after the copper tube and aluminum foil are combined), a protective layer is sprayed on the surface of the aluminum foil.

The first method has high processing efficiency and low cost, but the overall heat transfer performance of the heat exchanger is poor, while the latter is the opposite. The main difference is shown in the figure below:

Condenser aluminum tube aluminum fin anti-corrosion coating structure comparison chart

In the above figure, the left figure shows the structure of the copper tube aluminum fin condenser with anti-corrosion coating, and the right figure shows the condenser structure with post-anti-corrosion coating. Among them, the anti-corrosion coating structure has an additional layer of anti-corrosion coating between the fins and the copper tubes compared to the post-anti-corrosion coating structure. According to the principle of heat transfer, this coating has a greater impact on the heat transfer performance of the heat exchanger. In order to achieve better protection performance and ensure heat transfer efficiency, the post-protection coating process should be used first.

There are two process methods for implementing post-protective coating:

- On-site spraying

- Factory-specific equipment spraying

Obviously, the quality of spraying by factory-specific equipment is better, with the characteristics of thinner coating (lower thermal resistance) and more uniform (lower average thermal resistance).

As a typical representative of condenser protective coatings, Blygold gold foil anti-corrosion coating is the best product on the market. This anti-corrosion coating is a polyurethane aluminum compound with excellent weather resistance and good thermal conductivity. It only needs to be sprayed with a very thin layer on the surface of the heat exchanger to provide good and lasting protection for the condenser without reducing the heat transfer capacity of the condenser.

The main characteristics of Blygold coatings for condenser protection are as follows:

| name: | Blygold PoluAl XT |

| Paint Type: | Colored polyurethane aluminum |

| color: | champagne |

| Preprocessing | Removing oil stains |

| Temperature range (dryness): | -20°C to 150°C (-4°F to 302°F) |

| Applications: | Aluminum and copper |

| ASTM B117: | 4000+ hours (moderate salt spray test) |

| ASTM B-287: | 4000+ hours (acid salt spray test) |

| Sulfur resistance test: | 80 cycles |

| Coating thickness: | 25-30 μm (1 mil) |

| Impact test: | 0-5% (related to the geometric characteristics of aluminum foil) |

| Thermal resistance: | 0-3% (related to the geometric characteristics of aluminum foil) |

| operate: | Professional operators |

| UV resistance: | Excellent |

| Adhesion (planning method): | 0 (Europe) 5b (America) |

| application: | Corroded heat exchanger surfaces |

| Chemical resistance: | Excellent |

Finally, it should be noted that although the use of anti-corrosion coating on the condenser increases the cost to a certain extent, the proportion of this cost is not large compared to the whole air conditioner. What is important is that the energy cost saved in the entire life cycle of the air conditioner is considerable, and the maintenance cost is also reduced. It is recommended that users, especially users of computer room air conditioner products, pay full attention to the application of this technology, because computer room air conditioner products work 8760 hours a year, and its advantages and cumulative benefits are very obvious.