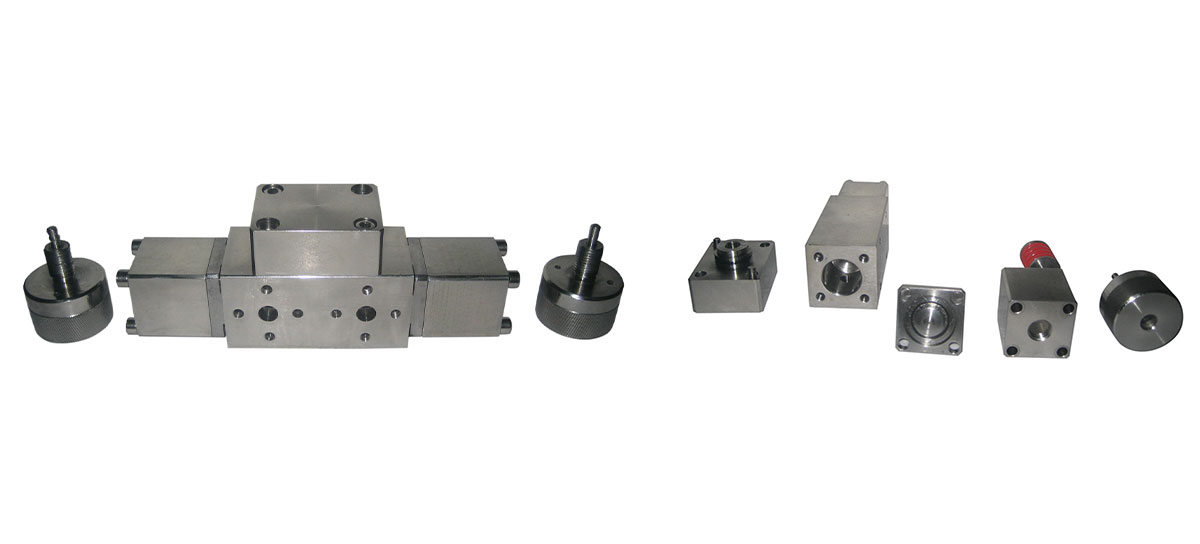

Mixing head for polyurethane continuous production line

This component is the core of the chemical reaction and mixing process during the continuous production of polyurethane sandwich panels. Developed in Germany specifically for the continuous production of polyurethane sandwich panels, this equipment features high mixing efficiency, durability, consistent performance, long-term cleaning requirements, easy installation, online pressure adjustment, and a compact size. Overall design principle: High-pressure liquid is ejected through small orifices, atomized and mixed within the chamber, achieving uniform mixing.1. System Configuration

Mixing Chamber: A precise, small cylindrical cavity where ISO and POLY collide and mix. Its inner walls are extremely hard to withstand the impact of high-pressure raw materials.

Nozzles: The passage through which raw materials enter the mixing chamber. Typically, multiple symmetrically arranged, extremely small nozzles are used to ensure a high-speed jet of raw materials.

Piston (Cleaning Rod): A precision piston that moves back and forth within the mixing chamber.

Mixing Position: The piston retracts, opening the mixing chamber and allowing raw materials to enter and mix.

Cleaning Position: The piston advances, completely expelling any remaining raw materials from the mixing chamber, thus cleaning the chamber.

Hydraulic Drive System: Provides powerful power for the reciprocating motion of the piston, controlling its timing and speed.

Material Line Interface: Connects to the ISO and POLY high-pressure lines from the high-pressure foaming machine.

2. Workflow (One Mixing Cycle)

Preparation (Cleaning Mode): The striker is in the forward position, closing the mixing chamber outlet to prevent air from entering.

Injection Mixing: The PLC issues a command, activating the high-pressure pump and pressurizing the ISO and POLY mixture to 150-200 bar. The striker instantly withdraws, opening the mixing chamber. Two high-pressure streams of raw materials are ejected and collided at high speed through the nozzle, creating intense turbulence in the mixing chamber and instantly mixing them. The mixture is then poured from the outlet onto the lower panel.

Self-Cleaning: Once the preset injection time (usually only 1-3 seconds) expires, the striker hydraulically advances rapidly, thoroughly and cleanly expelling any remaining liquid from the mixing chamber, preparing for the next injection.

Wait: The striker remains in the forward position, awaiting the next cycle command.

Previous

Automatic CNC reciprocating band sawNext

plunger pumpYou Might Also Like

Send Inquiry