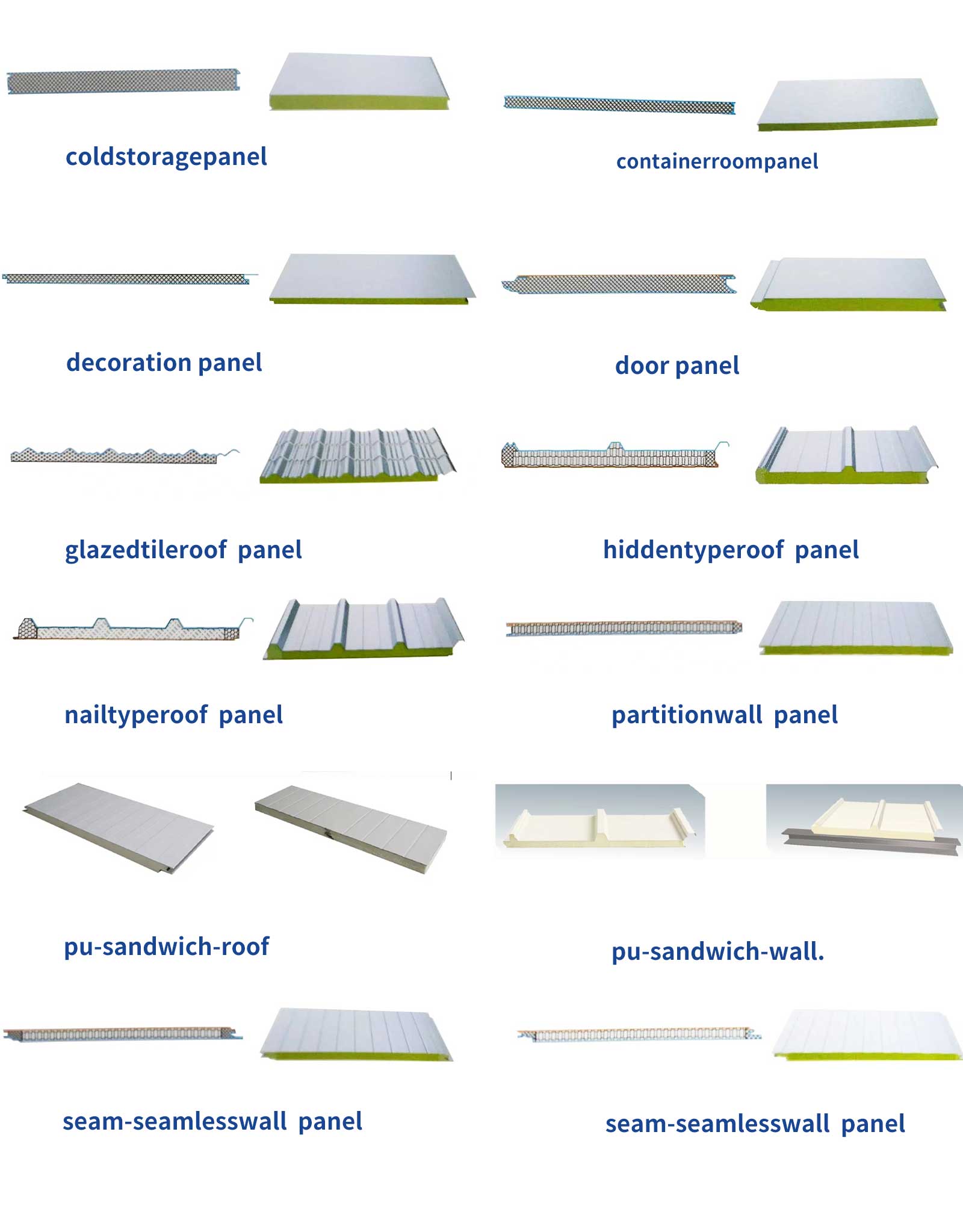

PU Board Making Machine

A PU panel making machine generally refers to a complete production line that produces sandwich insulation panels using polyurethane (PU) or polyisocyanurate (PIR) as the core material and metal sheets (such as color-coated steel sheets) or non-metallic sheets as the surface layer, through a continuous foaming and composite molding process. It is not a single machine, but rather an automated system integrating mechanics, chemicals, hydraulics, and electronic controls. Its core function is to mix two liquid chemical raw materials (isocyanate ISO and composite polyether POLY) under high pressure and evenly pour them between the continuously moving upper and lower panels. Under precisely controlled temperature and pressure, the mixture instantly foams and cures, firmly bonding to the panels, ultimately forming a continuous sandwich panel with excellent thermal insulation properties.Core Components (A complete PU board making machine typically includes):

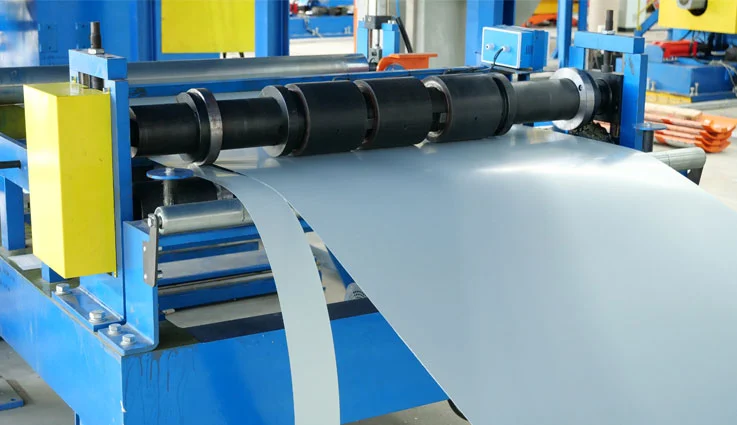

1. Unwinding System: Loads and unwinds the metal surface layer coil.

2. Roll Forming System: Rolls the flat metal coil into the desired sheet shape (such as corrugated, tongue-and-groove, etc.).

3. Foaming System (Heart):

High-Pressure Foaming Machine: The core of the core. It is responsible for mixing the ISO and POLY raw materials in a precise ratio under high pressure through an impact process, ensuring an extremely uniform mixture.

Depositing Head: Sprays or pours the mixed liquid evenly onto the moving lower sheet.

4. Double-Belt Laminator (Crawler Laminator): Provides the core reaction chamber. Two large heated platen belts form a moving pressurized chamber where the raw materials foam, cure, and form.

5. Cooling System: Cools the high-temperature cured sheet to room temperature to ensure dimensional stability and facilitate subsequent cutting.

6. Cutting System (Flying Saw): Precisely cuts the sheet into the desired length as it continues to move.

7. Stacking and Packaging System: Automatically collects, stacks, and packages finished boards.

8. Central Control System: An industrial computer (PLC) controls the entire production process, precisely adjusting all parameters, including recipe, temperature, pressure, and speed.

You Might Also Like

Send Inquiry