PU – PIR Sandwich Panel Production Line

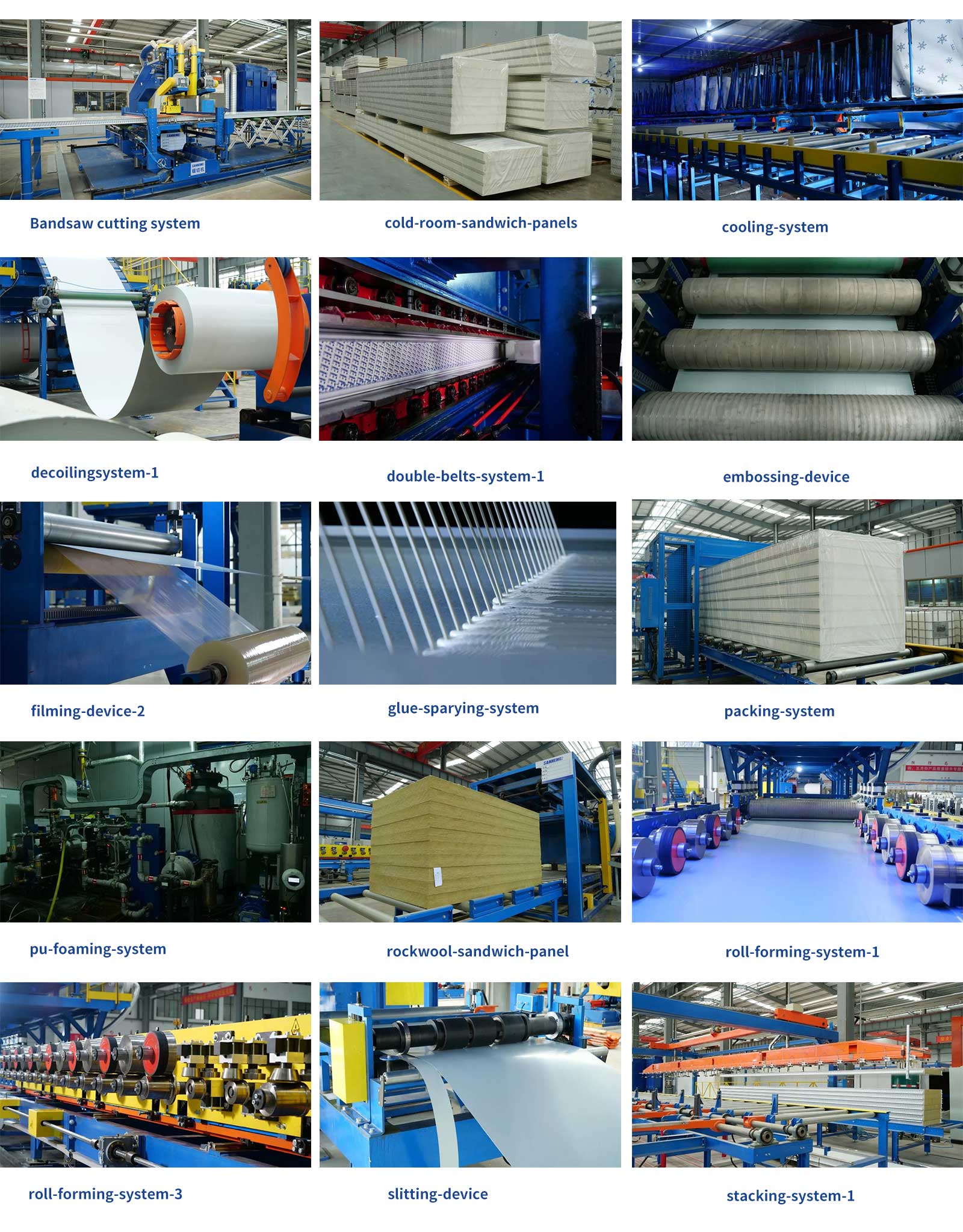

PU-PIR sandwich panel production lines are specialized equipment systems used to produce metal-faced sandwich panels with polyurethane (PU) and polyisocyanurate (PIR) as core materials. These lines are typically highly automated and continuous, designed to efficiently produce building panels with excellent thermal insulation, fire resistance, and structural strength. System Components

System Components

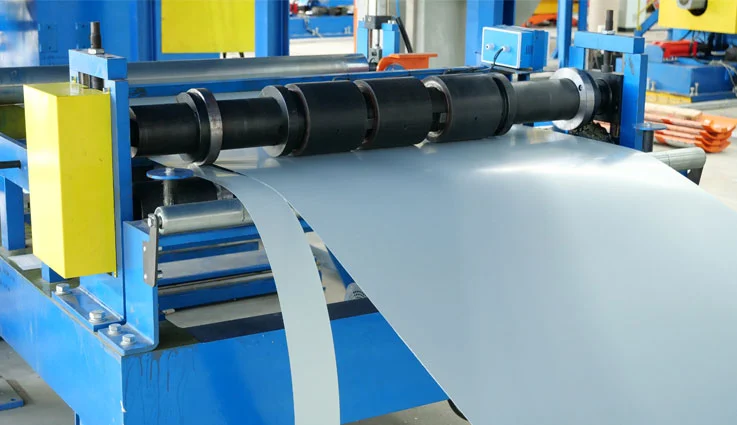

1. Uncoiling and Pretreatment System: Responsible for unwinding, cleaning, gluing (if necessary), and drying pre-treatment of metal panels such as color-coated steel sheets.

2. Roll Forming System: A series of precision rollers roll the metal panels into the desired shape (e.g., corrugated, flat, etc.).

3. PU/PIR Foaming System: This is the core of the production line. A high-pressure foaming machine pours a uniformly mixed PU or PIR liquid material onto the moving lower metal panel. The PIR formulation can be enhanced by adding an excess of isocyanate to create a denser cross-linked structure, improving heat resistance and flame retardancy.

4. Double-Belt Laminator (Crawler Type): Provides continuous pressure and heating to foam, cure, and firmly bond the core material between the upper and lower metal panels, forming a continuous sandwich structure.

5. Curing and Cooling System: Ensures the foaming reaction is fully completed and allows the sheet to gradually cool and set.

Cutting System: A flying saw or other automated cutting device precisely cuts the continuously produced sheet into the desired length. 6. Stacking and packaging system: Automatically collect, stack and package the finished panels for easy storage and transportation.

Previous

EPS Sandwich Panel Production LineYou Might Also Like

Send Inquiry