Rock Wool Sandwich Panel Machine

The rock wool sandwich panel machine is a specialized equipment system that continuously presses prefabricated rock wool core material and metal face sheets together using a physical lamination and gluing process. Its core technology lies in the synchronized cutting of rock wool to length, high-precision placement, uniform adhesive application, and high-pressure lamination. It does not produce the core material through chemical foaming, but rather efficiently laminates existing core material. It is a core equipment specifically designed for producing the highest fire-resistant grade (Class A) building sandwich panels. It utilizes a completely different technology approach from PU/PIR production lines and is an irreplaceable solution for the market demanding "extreme fire protection."

The rock wool sandwich panel machine is a specialized equipment system designed to produce composite sandwich panels with rock wool as the core material and color-coated steel or other metal panels as the facings.

Its core function is to automatically align prefabricated rock wool felt strips (or strips) with upper and lower metal panels, apply adhesive (spray adhesive), pressurize and laminate, and cure, ultimately creating a continuous sandwich panel with excellent fire resistance (Class A), thermal insulation, and sound insulation properties.

A standard rock wool sandwich panel continuous production line mainly includes the following systems:

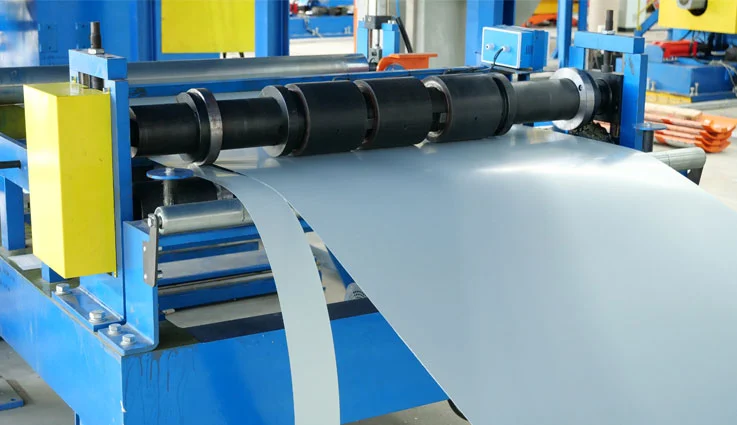

1. Unwinding System: Loads and unwinds the upper and lower metal facing coils.

2. Roll Forming System: Presses the upper and lower metal panels into the desired shape (e.g., concealed button or exposed nail).

3. Rock Wool Conveying and Cutting-to-Length System: This is the core feature of the rock wool line. It smoothly conveys prefabricated rock wool mats and precisely cuts them to the desired length.

4. Spreading System: Precisely delivers the cut rock wool strips to the center of the lower metal panel.

5. Heating and Curing System: Heats the laminated panels to accelerate the curing of the adhesive.

6. Cooling and Setting System: Cools the heated panels to room temperature to fully cure the adhesive and set the panel shape.

7. Cutting System: Cuts the continuously laminated panels to length.

You Might Also Like

Send Inquiry