rockwool sandwich panel production line

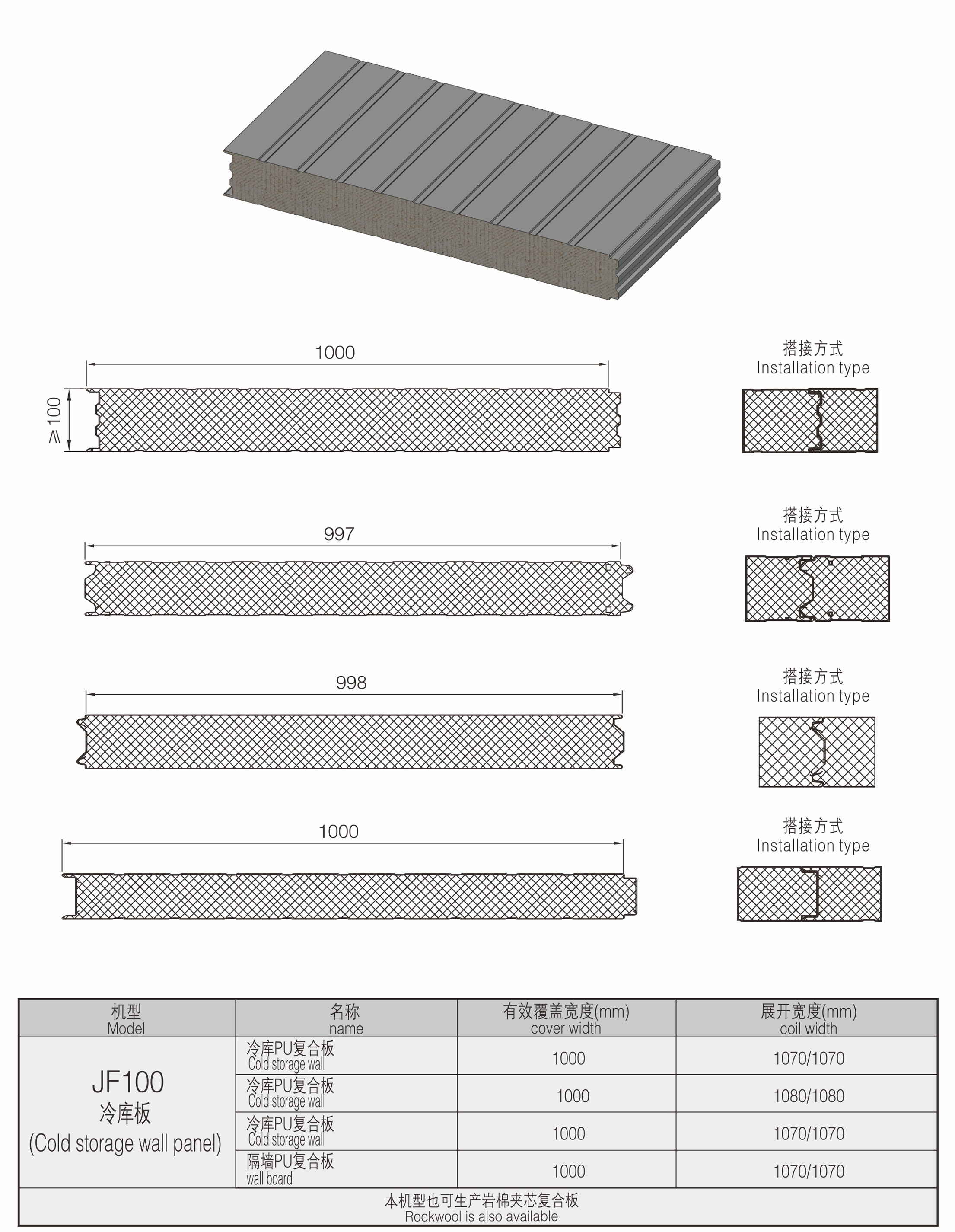

Main Parameters of Rockwool Continuous Sandwich Panel Production Line Sandwich panel specification: Length: Min cutting length is 2.5 m Max cutting length is 12m Width: (see profile dra...Main Parameters of Rockwool Continuous Sandwich Panel Production Line

Sandwich panel specification:

Length: Min cutting length is 2.5 m

Max cutting length is 12m

Width: (see profile drawing)

Thickness: (see profile drawing)

Raw material specification:

coil thickness: 0.4~0.6 mm (steel be flat without ups and downs, deformation and bending)

sheet yield stress: ≤235MPa

coil max width: 1250 mm (tolerance±2mm)

coil max weight: 5T

coil ID: Φ500 and Φ600 mm

coil OD: Φ1000 mm

Rock wool material: fiber length is >100mm, and the fiber should be arranged vertically, volume density is ≥70kg/m3, one-piece length is ≥3m.

EPS material: volume density is ≥18kg/m3, each edge nonstraightness is ≤1mm/m, radian is ≤3mm/m, the panel surface should be flat, roughness is <1.5mm/m, EPS panel one-piece length is ≥3m.

EPS material width: min width is 1/2mm of the sandwich panel width.

Machine rockwool specification:

Work line speed: 4000m/min (adjustable)

Machine length: about 70 m

Working height: 1050 mm(panel output height)

Laminating effective length: 7.5m

Control way: adopt industrial computer PLC

Total power: about 45 kw

Power: 380V/3phase/50 Hz

control voltage: 24 V/110 V/220 V

pneumatic: 0.7 Mpa (self-prepared by the factory)

best working temperature: around 25℃

Component List of Rock Wool Sandwich Panel Production Line

| No. | Component | Qty | Remarks |

| 1 | 5T passive decoiler (upper forming system) | 1set | Loading capacity is ≤5t |

| 2 | Upper roll forming machine | 1set | With slitting and waste edge winder |

| Lower roll forming machine | 1set | ||

| Connecting roller of upper & lower forming system | Each 1set | ||

| Platform, stair and rail of upper roll forming machine | 1set | ||

| 3 | Rock wool transfer device | 1set | |

| Rock wool edge cutting device | 1set | ||

| Dust collector | 1set | ||

| 4 | Rock wool clamp device | Each 1 set | |

| 5 | Laminator host | 1set | Effective length 7.5m |

| 6 | Saw cutting system | 1set | Upper & lower saw |

| 7 | Support frame | 3sets | |

| 8 | Electric control system | 1set |

Panel Drawings Of Rockwool Continuous Sandwich Panel Production Line

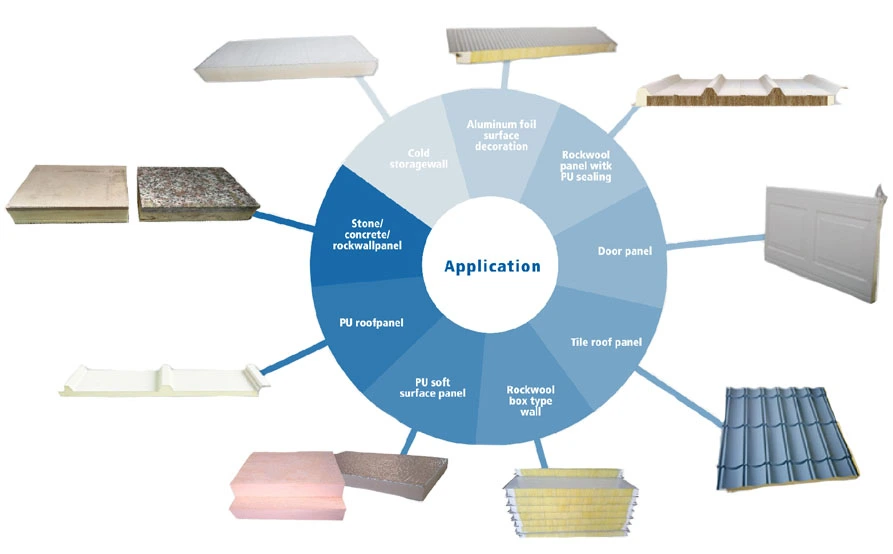

Application of Rockwool Continuous Sandwich Panel Production Line

application: stone/concrete/rock wall panel, cold storage wall, aluminum foil surface decoration, rock wool panel with PU sealing, door panel, tile roof panel, rockwool box type wall, PU soft surface panel, PU roof panel.

You Might Also Like

Send Inquiry