Roll Forming System

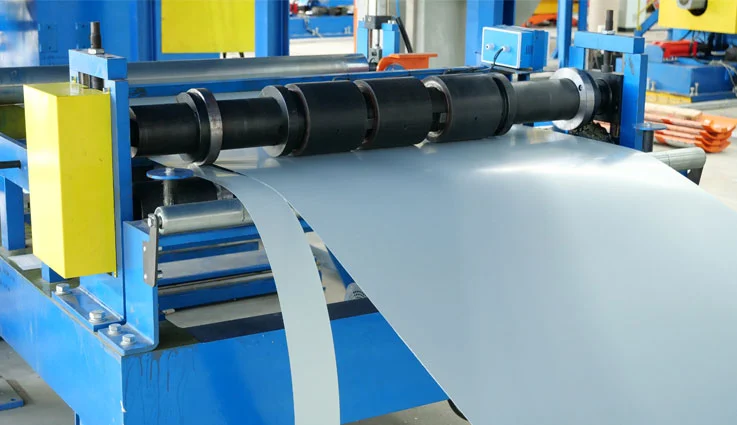

A roll-forming system, also known as a cold-roll forming system or flow-forming system, is a key front-end process in a continuous sandwich panel production line. Its core function is to continuously plastically deform flat metal sheets (such as color-coated steel and galvanized steel) supplied in coil form at room temperature using multiple pairs of precisely contoured rollers arranged in a specific sequence, gradually rolling them into the specific cross-sectional shape required by the design, thus providing qualified panels for subsequent foaming and lamination. Simply put, it's a "metal sculptor," "sculpting" the ordinary metal coil into the final sandwich panel shape.1. System Configuration

A typical roll forming system consists of the following components:

Frame: A sturdy steel structural frame that supports all roll shafts and bearings.

Roller stack (station): The heart of the system. It consists of dozens or even hundreds of pairs of precisely designed and machined upper and lower rolls, mounted sequentially on multiple parallel shafts. Each roll pair performs a small, gradual deformation step.

Drive System: Typically, a high-power motor drives all or some of the roll shafts through a gearbox, universal coupling, and other mechanisms to synchronize the rotation of the rolls, providing power for the sheet metal to advance.

Guiding and Adjusting Devices: Ensures that the coil enters the first set of rolls flat and centered; it also allows for fine-tuning of the roll gap and levelness to compensate for sheet thickness tolerances or wear.

Lubrication System (Optional): In some cases, minimal lubrication is applied to the rolls or sheet metal to reduce friction and wear and achieve a smoother surface.

Control System: Connected to the main production line PLC, it controls the speed of the drive motors and ensures synchronization with the production line.

2. Workflow (“Incremental Deformation” Principle)

This is the essence of roll forming technology, and the process is like a “zipper in slow motion”:

Input: The flat metal strip from the unwinding system is precisely centered and fed into the first pair of rollers.

Incremental Forming:

The first pair of rollers applies only the simplest deformation, such as creating a slight arc or raising a preliminary edge.

The sheet then moves forward and enters the second pair of rollers, which further deform the sheet based on the previous pair.

This process continues in this gradual manner, with each roll station bringing the sheet’s cross-sectional shape closer to the final design.

Final Forming: After passing through all roll stations, the metal strip emerges from the outlet as a fully formed panel with the required complex three-dimensional cross-section.

Output: The formed panel is directly conveyed to the next process (usually the laminator entrance) for lamination with the core material.

Gallery of Polyurethane Continuous Sandwich Panel Production Line

You Might Also Like

Send Inquiry