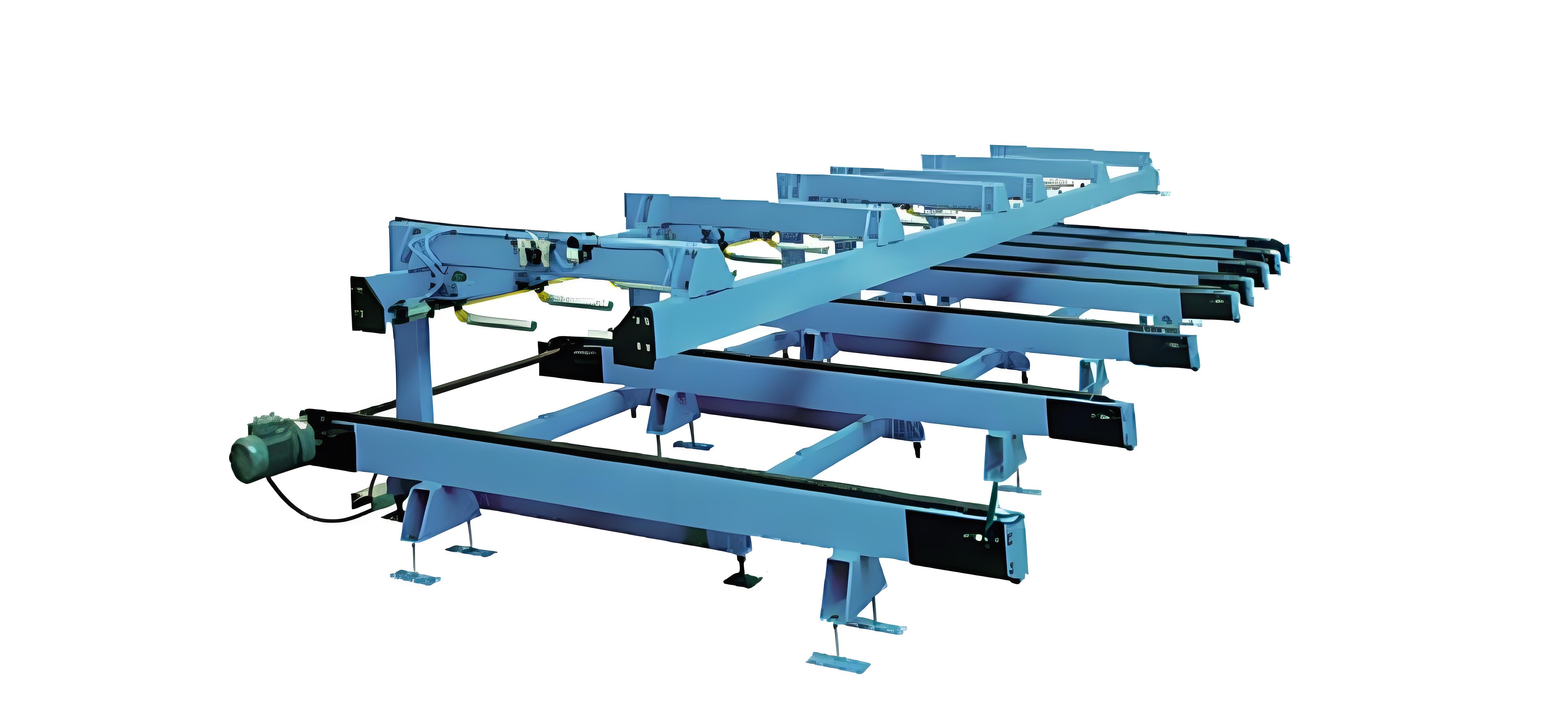

Stacker

A stacker is an automated material handling device at the end of a continuous sandwich panel production line. Its core function is to receive individual finished panels from the cutting system and, using gripping mechanisms such as vacuum cups or robotic arms, accurately, efficiently, and non-destructively grasp and stack them into neat stacks, preparing them for final packaging and shipping. Simply put, it serves as the "robotic transporter" of the entire production process, automating the transition from continuous production to organized stacking.

Stackers are typically located after the cutting system at the end of the production line.

1. System Configuration

Frame and Travel Mechanism: A sturdy gantry-style frame or column mounted on high-precision linear guides and driven by servo motors, enabling precise movement perpendicular to the production line.

Lifting Mechanism: Attached to the frame, this mechanism drives the gripper mechanism up and down to accommodate varying gripping and release heights.

Gripper: This is the “hand” of the stacker. The most common types are:

Vacuum Suction Cup Assembly: A lifting device consisting of multiple vacuum cups (usually made of rubber or polyurethane). A vacuum pump generates negative pressure, which grips the non-decorative surface (usually the back) of the sheet material, enabling non-destructive gripping. This is the most popular and user-friendly method.

Mechanical Gripper: In some specialized cases, a robotic arm may be used to grip the sheet material edges, but this is less common due to the risk of injury.

Stacking Platform (Lifting Table): Used to receive stacked sheets. Its core feature is its automatic lowering function: with each sheet stacked, the platform automatically descends by the thickness of the sheet, ensuring that the top layer of the stack and the gripper are always at a fixed, optimal working height. This significantly improves pick-and-place efficiency and saves energy.

Control System: Connected to the production line’s main PLC, it receives signals such as sheet position, length, and stack quantity, and precisely controls the timing and position of all actions—moving, lifting, picking up, and releasing.

2. Workflow (“Grab-Move-Place” Cycle)

Waiting in Position: The stacker moves to the production line’s sheet discharge position and waits, with the stacking platform at its highest point.

Grabbing Sheets: After cutting, individual sheets are transported to the gripping station. The lifting mechanism descends, and the vacuum cups contact the sheet surface, activating the vacuum to securely hold the sheet.

Lifting and Traversing: The lifting mechanism rises, slightly lifting the sheet, and the entire gantry moves laterally, delivering the sheet directly above the stacking platform.

Sheet Release: The lifting mechanism descends, precisely placing the sheet onto the stacking platform (or already stacked sheets), then the vacuum releases and the suction cups return.

Platform Lowering: The stacking platform automatically descends by the thickness of the sheet.

Return to Position: The stacker crane moves laterally back to the production line’s sheet discharge position, waiting to pick up the next sheet, and the cycle repeats.

Full Stack Output: When the stacking quantity reaches a preset value (e.g., a stack of 50 sheets), the stacking platform descends to its lowest position, allowing a forklift or AGV to remove the entire stack. The platform then automatically returns to its highest position to begin stacking the next sheet.

You Might Also Like

Send Inquiry