According to its driving mode, structural characteristics and applicable scope, it can be divided into many types. The following are some common types of uncoilers:

1. Classification by driving mode

Mechanical uncoiler: It mainly relies on mechanical transmission devices, such as gears, chains, belts, etc., to transmit the power of the motor to the reel to achieve the unwinding of the coil. Its advantages are simple structure, low cost and easy maintenance.

Hydraulic uncoiler: The hydraulic system is used to drive the coil rotation and control the tension. The hydraulic system has a large output force and can easily handle large and heavy coils, with fast response speed and high tension control accuracy.

Pneumatic unwinder: uses compressed air as the power source and drives the reel to rotate through pneumatic components. It is clean, safe and low-cost, suitable for small rolls and places with high environmental requirements, such as unwinding plastic films, paper and other rolls in the food and pharmaceutical packaging industries.

2. Classification by structural characteristics

Cantilever uncoiler: Its structural feature is that one end of the coil is fixed and the other end is cantilevered. This type of uncoiler is convenient for loading and unloading, simple to operate, and suitable for narrow coils or light coils, such as the uncoiler of narrow copper and aluminum strips in the electronics industry.

Double cone head uncoiler: It adopts double cone head structure and fixes the coil by tightening the cone head. It can adapt to coils with different inner diameters and has high positioning accuracy for coils. It is often used in occasions with high requirements for uncoil accuracy, such as high-precision plate processing production lines.

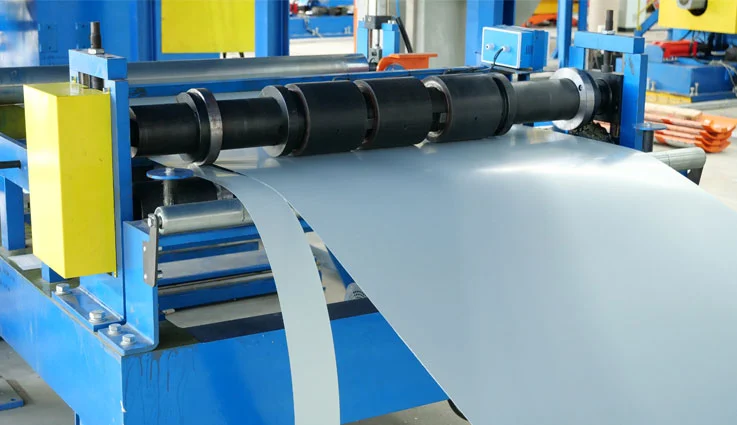

Belt uncoiler: The steel belt or rubber belt contacts the surface of the coil and uses friction to drive the coil to unwind. It causes less damage to the surface of the coil and is suitable for unwinding materials with high surface quality requirements, such as stainless steel sheets, non-ferrous metal foils, etc.

3. Classification by degree of automation

Manual decoiler: It requires manual loading, unloading and some operations during the coil unwinding process. It has a low degree of automation and is suitable for small batches and simple processing. It has a low cost.

Semi-automatic uncoiler: Some operations are automated, such as the rotation of the roll and the control of tension, but some work still requires manual assistance, such as loading and unloading, and is suitable for medium-sized production enterprises.

Fully automatic uncoiler: It is highly automated and can realize the automatic operation of the entire process of automatic loading, unloading, uncoiling and tension control of coils. It has high production efficiency and is suitable for large-scale and high-efficiency production lines, such as the continuous production lines of large steel mills.

If you are interested in the uncoiler, we strongly recommend you to visit www.wxjyequipment.com. Here you can find detailed information about the uncoiler.