Replacing the condenser is a key link in the maintenance of the refrigeration cycle. It is necessary to follow the standardized process to ensure that the system resumes efficient operation. Before operation, it is necessary to confirm the refrigerant type and system pressure parameters. Wear protective equipment including goggles, antifreeze gloves and anti-static work clothes. Prepare torque wrench, expander, vacuum pump, refrigerant filling equipment, leak detector, and pressure gauge set in the tool kit.

Turn off the power of the compressor and hang a warning sign. Use a composite pressure gauge to connect the high and low pressure inspection valves to slowly release the residual pressure of the system to below 0.1MPa. Take photos of the pipeline connection before disassembling the condenser for archiving, and mark the corresponding relationship between the refrigerant flow direction and the circuit interface. When cutting the inlet and outlet copper pipes with a pipe cutter, keep the cut flat to prevent metal debris from entering the system. When removing the fixing bracket bolts, pay attention to distinguish fasteners of different specifications. It is recommended to use a magnetic suction tray for classified storage.

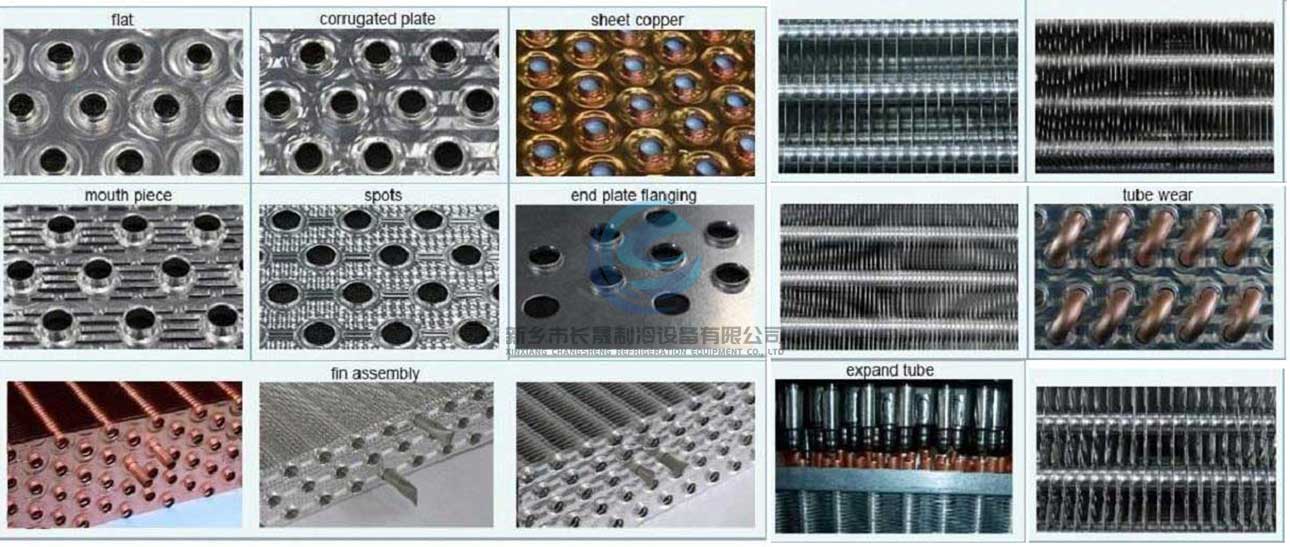

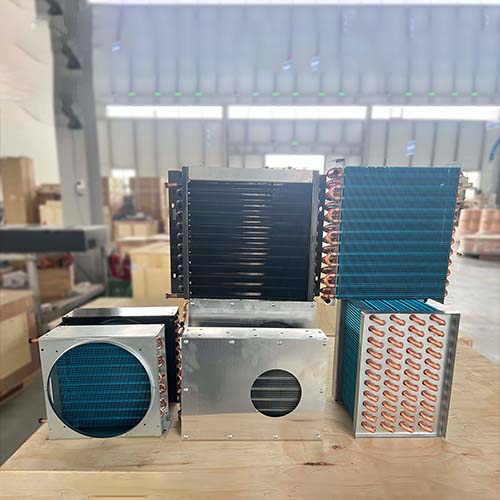

Before installing the new condenser, an airtightness test is required. Fill the heat exchanger with 1.5MPa nitrogen for 24 hours. The pressure drop does not exceed 0.02MPa to be qualified. Low-silver phosphor copper electrodes are used for pipeline welding, and the welding temperature is controlled in the range of 700-800℃. Immediately after welding, nitrogen is used to purge the pipeline to eliminate the oxide layer. Pay special attention to the repair of the insulation layer at the connection between the expansion valve and the liquid reservoir, and use high-temperature resistant ceramic fiber tape to wrap more than three layers.

During the vacuum stage, a three-stage vacuum pump group is used for relay operation. After the initial rough pumping to 500Pa, the molecular sieve pump is switched. The final vacuum degree must reach below 20Pa and maintain for 2 hours. When filling the refrigerant, an electronic scale is used for measurement. First, fill the nominal amount of 80

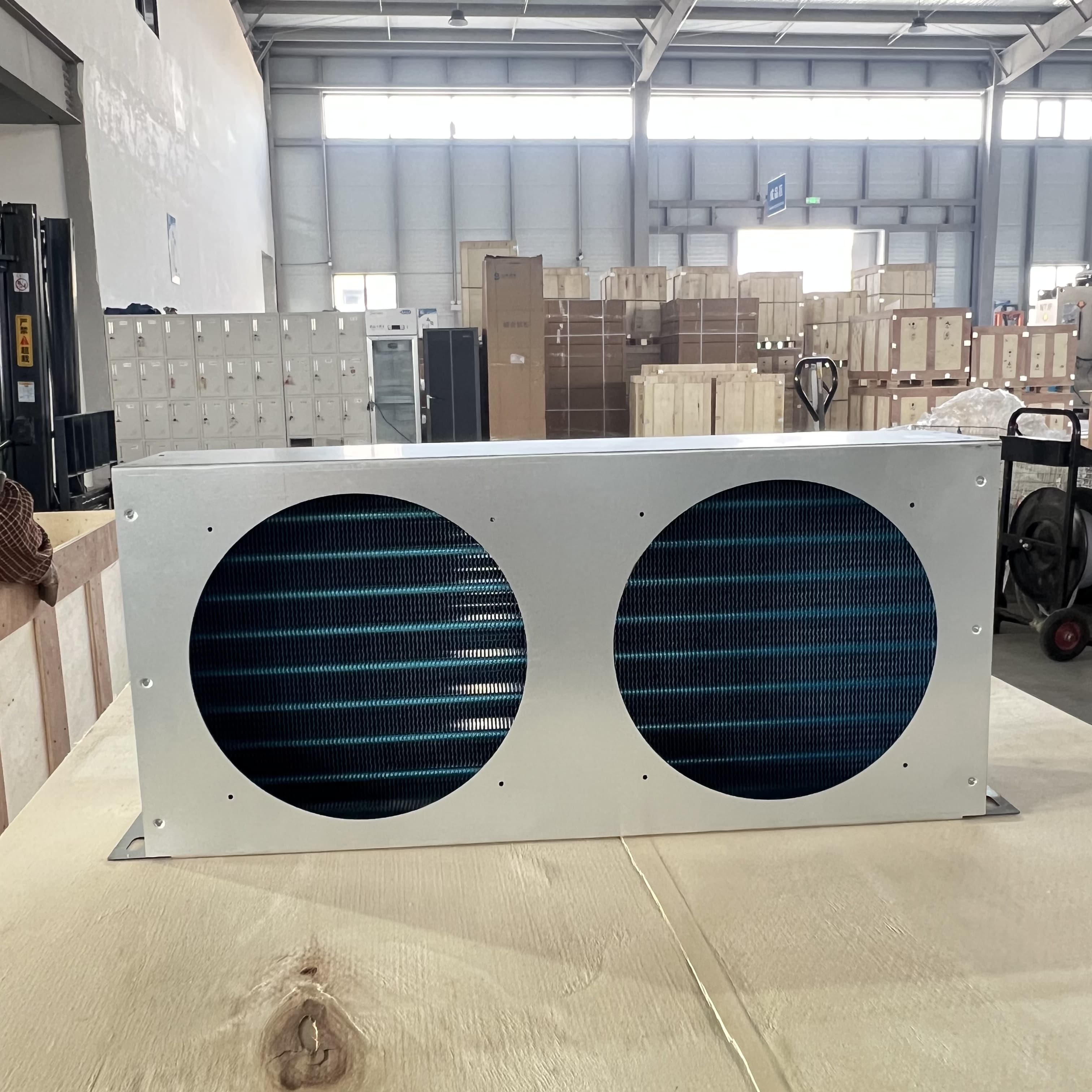

Common fault handling includes troubleshooting of condensate discharge, and using an endoscope to detect whether the slope of the drain pipe meets the 3° inclination requirement. The fins are cleaned with a neutral detergent and a soft brush for reverse combing, and the flushing water pressure does not exceed 0.3MPa. Regular maintenance recommends using a thermal imager to detect the temperature distribution of the pipeline every quarter. Abnormally high temperature points indicate possible micro-leaks or pipeline blockages.

The tool and material list should include: • R410A special charging hose (pressure resistance 50bar) • Double-ended ratchet wrench set (8-19mm specification) • Electronic micromanometer (range 0-5kPa) • Pipe positioning fixture (304 stainless steel) • Refrigerant recovery device (with automatic oil separation function)

Safety regulations include: 1. The refrigerant storage area is equipped with a forced ventilation system, and the concentration alarm setting value is lower than 1500ppm 2. Two people are required to work together in a confined space and carry an oxygen content detector 3. Waste refrigeration oil is handled according to hazardous chemicals standards and temporarily stored in a special recovery container

Process quality control node settings: – Welding joint 100 – Residual moisture content after vacuuming ≤100ppm – System operating noise is reduced by more than 3dB compared to before maintenance – Energy efficiency ratio is restored to 95% of the original factory nominal value

Maintenance file record elements include equipment serial number, refrigerant batch number, vacuum curve, trial operation data table and maintenance personnel qualification certificate number. It is recommended to establish an electronic management system to achieve dynamic association between maintenance records and component information through scanning equipment.